The CNC Control Unit

What would you do if you could bend any tube, of any length, to any angle, with a single set-up? The answer comes with the control unit of the CNC tube bender.

The first touchpoint involves the tube length calculation: you input information about the type of metal and how much it is supposed to flex, and the control unit calculates the length of the tube needed to bend it at exactly the right angle. The second touchpoint is the set-up itself: one touch and you’re done! The bender will automatically recognize which material is being used and how much it can flex, so its settings are always perfect.

The control unit has multiple modes of operation, including automatic, manual, and teach mode. In automatic mode, the controller uses pre-programmed cutting parameters to automatically complete a bend. Teach mode allows the operator to manually position the tooling while pressing a button on the control unit to indicate when each position has been reached. This allows for more precise positioning of tooling.

Teach Mode CNC Tube Bender Software

The CNC tube bender machine is a marvel of technology. It features a 12” touchscreen interface software that allows for easy setup of jobs and programming. The software is fitted with a Windows environment. The user can operate the software in either manual or automatic mode.

There are always two or three levels of interference zones between every pair of bends on your part. The software enables three-dimensional part display and stimulation. So, you can see exactly how complex a shape you’re trying to bend.

This software also allows you to calculate how long a tube needs to make a certain piece, as well as program roll bends and bend multiple tubes at once!

The software of the CNC tube bender machine will show an image of what your finished product will look like before you even start bending. This can provide a visual aid for planning out the best way to arrange your materials and make sure they’re all set up correctly.

3D Workpiece Stimulations. Three-Axis control console

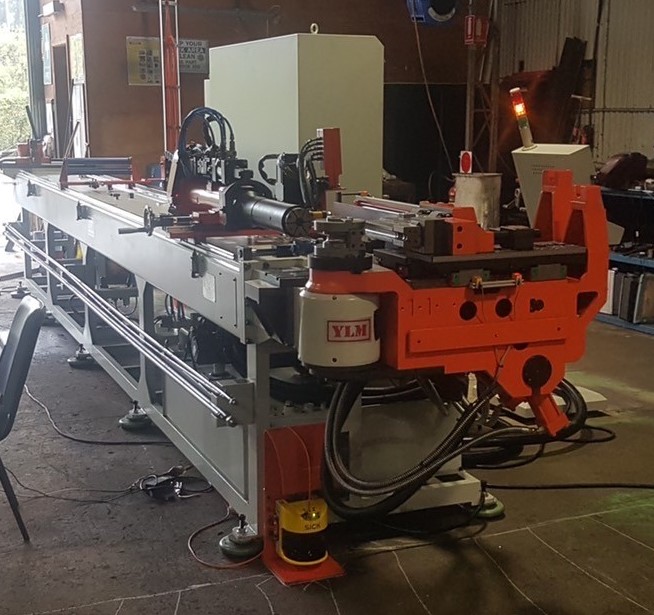

The CNC tube bender machine features a three-axis control console that allows you to easily change the bend angle and cycle time according to your needs. It also has a high-speed positioning system that enables efficient workpiece manipulation and accurate bending processes.

3D Workpiece Stimulations that help to give the overview of the final product and enable us to make changes before we start production. It’s like a virtual model of the final product and helps to make changes before starting. 3D Workpiece Stimulations can provide a visual aid for planning out the best way to arrange your materials and make sure they’re all set up correctly.

Auto lubrication system

The CNC tube bender machine is a powerful, fast and efficient tool that can handle all your bending needs. This machine is equipped with an auto lubrication system that ensures lubrication of the spindles at regular intervals. This helps to keep the machine in top condition for longer periods of time.

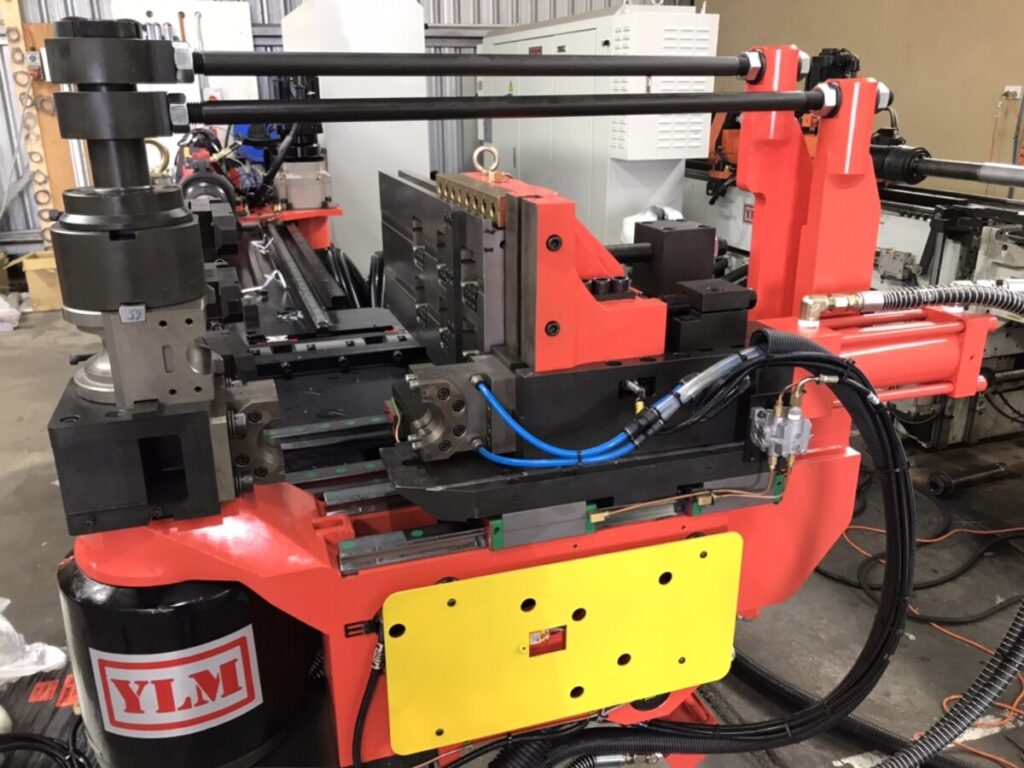

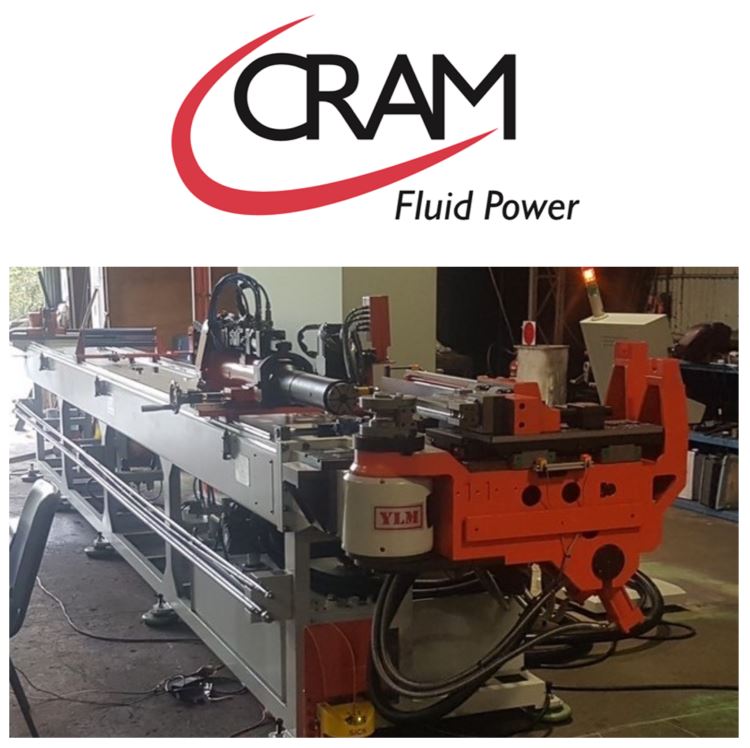

The YLM CNC tube bender is also equipped with an automatic loading system that allows for quick and easy loading of tubes into the machine. The machine has been designed to ensure maximum safety during operation. It also comes with a host of other features such as:

- Touchscreen controls

- Automatic rotary indexing table

- Auto lubrication system, etc.

High Machine output with fast bending speed

The YLM CNC tube benders are high-speed and high-quality machines that can be used to produce a wide range of tube bending requirements.

The machine’s 2-axis function can handle the processing of various tubes, and the operation is simple and convenient. It can also be used to handle various tube materials, such as steel, aluminium alloy, stainless steel, and copper alloy, so it is widely used in many industries.

Buy CNC Tube Bender at Delahenty Machinery

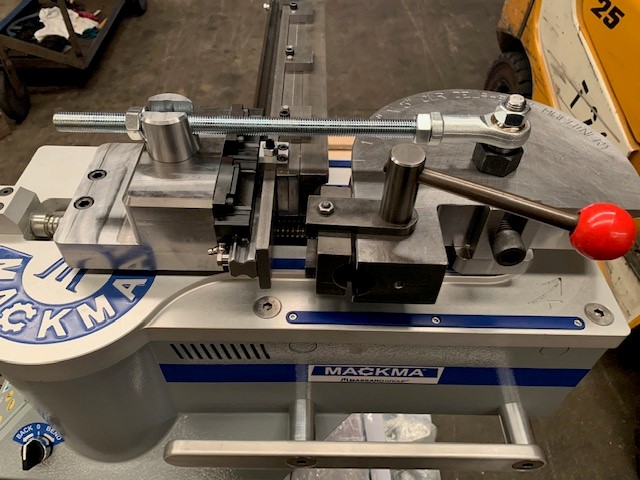

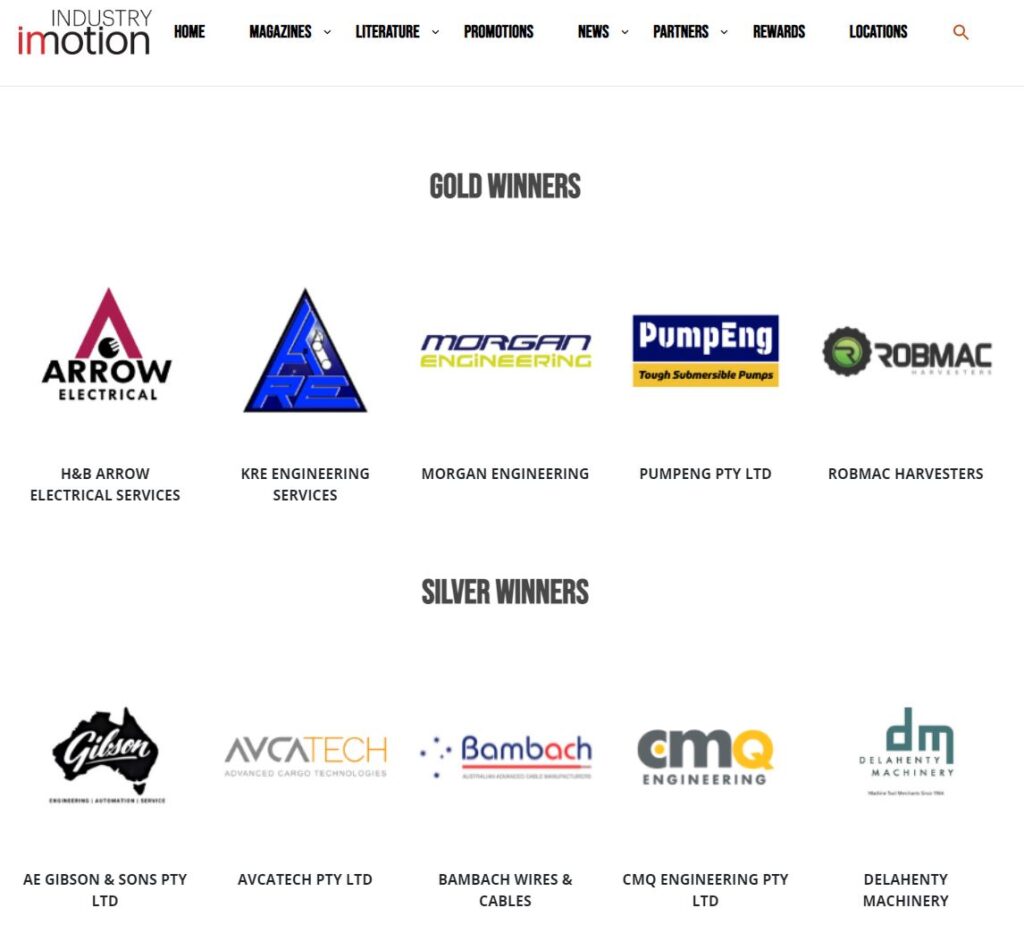

Start your adventure with our CNC tube bender machine. As one of the leading CNC tube bender manufacturers,Delahenty Machineryis always ready to provide you with various kinds of CNC benders — twin head tube benders, and full electric tube benders according to your demands and applications.

Our CNC tube benders are suitable for a wide range of industries, such as welding, construction and automotive, architecture, shipbuilding, heavy transportation, chemical engineering, and manufacturing. All of our machines feature high precision, stable performance, easy operation, and so on. We also provide various kinds of accessories to help you complete your bending jobs more efficiently. For example, we have section rollers for different jobs like (aluminium alloy, and steel). Contact us to know more.