YLM – CNC Hybrid Tube Bending Machine – CNC-80MS-5A

Specifications

| Make | YLM |

|---|---|

| Model | CNC-80MS-5A |

Description

YLM – CNC Hybrid Tube Bending Machine – CNC-80MS-5A

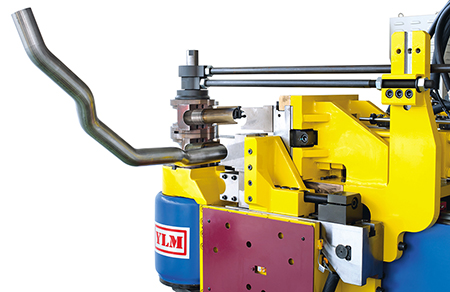

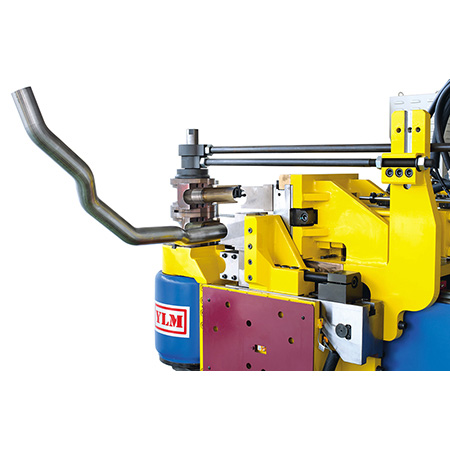

YLM produces a line of CNC hydraulic tube benders designed for the companies looking for an economical way to enter into CNC benders.

The machines are available in capacity sizes from 1-1/2” to 5”. Utilising the proven software technology these heavy duty benders will meet the needs of furniture manufacturers, automotive production, ship builders, or job shop applications.

Features of Hybrid Tube Bender

- The series of machine employs hydraulic valves and integrated circuits to control bending motion individually, which will extend the service life of the hydraulic parts.

- Large bending machine is equipped with a manually adjusted digital flow regulation valve to control the speed of bending motion.

- Servo drive provides high accuracy in bending positioning, that ensures high quality bending.

- Draw+Rollers-Bending

- 3D Simulation of Bending Process and application

- Standard machine design features on CNC benders include:

- Air conditioned electrical enclosure to maintain temperature and prolong system components

- Electrical power filtering to stabilise incoming power supplies for an efficient consistent operation

- Control electrical cabinet isolation to minimise vibration transfer to electronics

- Oil filtering system with condition indicator to protect oil supply

- Radiator type oil cooler standard on most models, available on others to maintain oil temperature

- Vibration control machine mounting pads to reduce machine movement during operation

- Spacious well labeled / layout of electrical system for ease of maintenance and efficient operation

- Remote control console for placement in operational location based on application to reduce operator interface time to increase production

- Foot pedal cycle start operation for quick safe loading increasing production

- Safety mat and safety plates with multiple emergency stop placement for operational safety

- Integrated gearbox reducer with multi layer drive chain assembly for smooth controlled operational start / stop movement of bend arm extending the chain life many years beyond traditional hydraulic benders.

- Low profile bend head design uniquely offset from center of machine frame providing clearance for complicated parts that can not be obtained on other brands of equipment.

- Full capacity feed through collect for working with long material that requires additional length beyond the front collect stop system reducing the need for extended models in most applications.

- Low decibel level production noise to reduce operator fatigue and general improvement of shop conditions

- Low working heights for ease of operation increasing production and improved safety of material handling

- Multiple axis operation reducing cycle time and interference for optimum production

Specifications:

Machine Name CNC-80MS-5A

- Max. tube o.d. bending capacity(Mild steel CLR1.5D)(mm) 76.2×2.8

- Range of CLR (mm) 250

- Max. bending radius difference (mm) 90

- Max. bending angle (°) 190

- Mandrel working distance (mm) 3000

- Manufacture speed Max. Tube feeding speed (mm/sec) 753

- Tube rotation speed (mm/sec) 180

- Max. Tube bending speed (mm/sec) 83

- Repeatability Tube feeding Precision (mm) ± 0.1

- Tube rotation Precision (mm) ± 0.1

- Tube bending Precision (mm) ± 0.1

- Overall weight (Kgs) 6560

- Machine length (mm) 6440

- Machine width (mm) 2195

- Machine height (mm) 1877

- Operating height (mm) 1164

Read about other companies that have bought similar YLM bending machines.