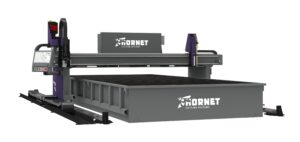

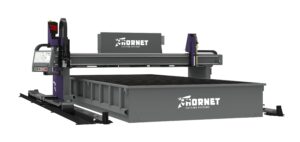

Hornet Mega 1000 CNC Plasma Cutting Machine

Specifications

| Make | Hornet |

|---|---|

| Model | 1000 CNC |

Description

Hornet Mega 1000 CNC Plasma Cutting Machine

The Mega Hornet 1000 CNC plasma cutting machine sets a new higher standard for accuracy, power and reliability in a heavy duty plasma cutter.

The Mega Hornet 1000 CNC plasma cutting machine has an enormous frame and massive servo drives to deliver decades of reliable service to shipyards, service centers and manufacturers. A welded and stress relieved gantry beam and fabricated steel end trucks enable the Mega Hornet 1000 CNC plasma cutter to span up to 14 feet (4.3m) and carry up to 6 cutting and marking processes. The CNC plasma machine includes the Hypertherm Edge Connect CNC control with support for True Hole™ and Rapid Part technology.

The Mega Hornet 1000 CNC plasma cutting machine incorporates the industry’s most reliable AC servo amplifiers and servo motors, precision planetary gearboxes, precision ground cross axis linear ways and a heavy duty machined floor mounted rail system.

This rugged CNC plasma table is designed for shipyards, service centers, contract shops and manufacturers and is available in widths from 6.6′ (2 m) to 14′ (4.3 m). Lengths of over 100′ (30 m) or more can be supplied.

Standard Features

- Hypertherm Edge Connect CNC control

- Integrated SENSOR torch height control interface

- Heavy duty steel gantry construction

- Dual 20mm Cross Axis Linear Ways

- Hardened and ground helical pinion gears

- Precision helical gear rack

- Triple machined floor mounted main rails

- Planetary gear heads

- 1,200 IPM (30 mpm) rapid traverse speed

- Enclosed flexible cable carriers on Both X & Y axis

- Flexible master carriage system for up to three tools

Options

- Widths from 6.6′ (2 m) to 14′ (4.3 m)

- Rail Systems to 100 ft (30.5 m) or More

- Up to six stations

- Up to two plasma cutting systems – conventional or high definition up to 800 Amps

- Plasma Torch Lifter with AC Servo Driven Ball Screw

- Plasma Torch Collision Mount

- Contour bevel system

- Up to two plasma torch height control stations

- Up to six oxy-fuel stations – straight cutting

- Digitally controlled heavy-duty electronic oxy-fuel gas manifold

- Phoenix software oxy-fuel cut chart screen captures

- Programmable Torch Selection and Spacing

- Over-head cable carriers

- Automatic Lubrication Systems

- AeroCLEAN multi-zoned down draft air table

- HydroCLEAN water table with adjustable water level

- Dust collection systems

- Programming software

- Plate Markers (air scribe or plasma)

- Cross-hair laser pointer