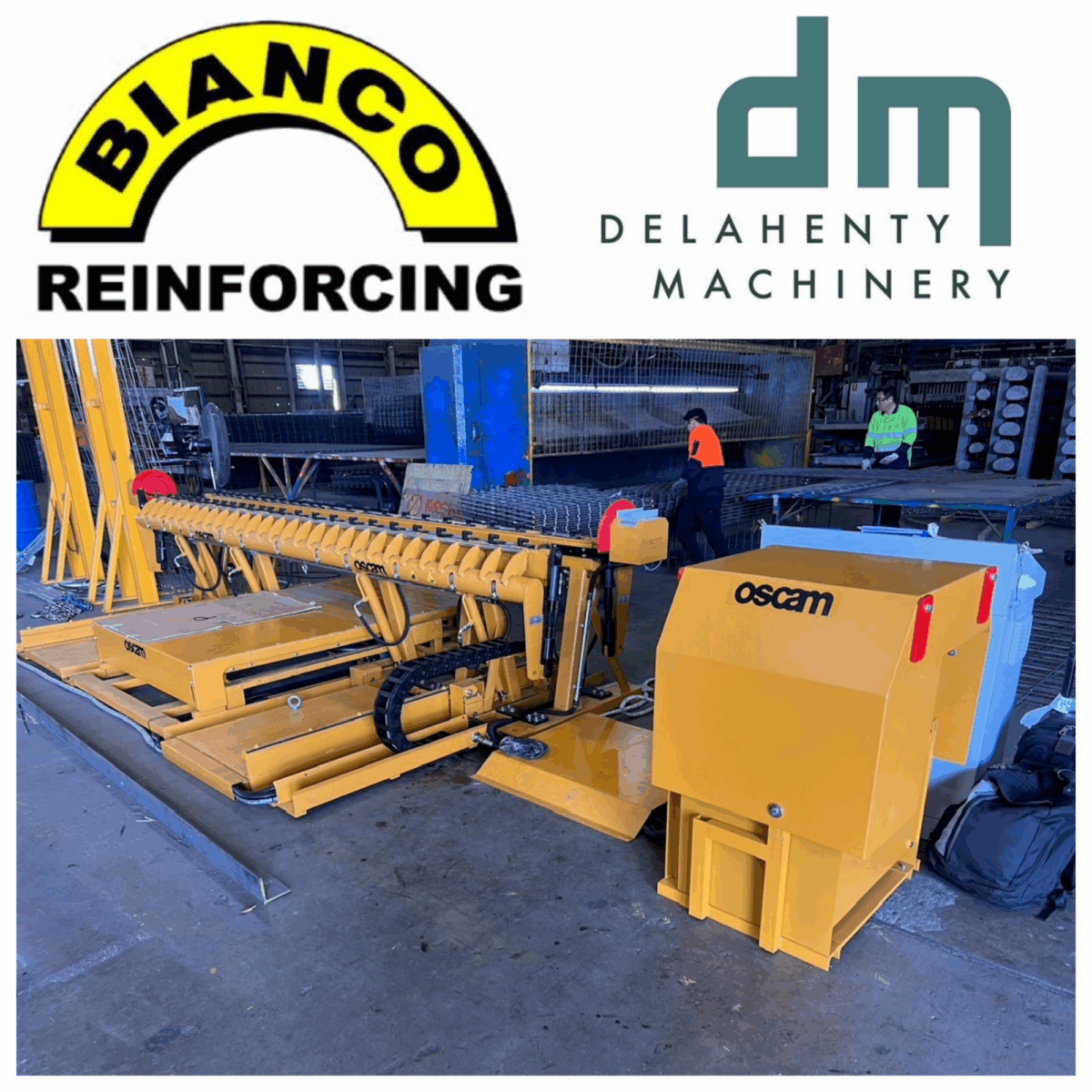

For businesses in the precast concrete and large-scale construction industries, reliance on manual mesh bending is a bottleneck to growth. High-volume, complex projects demand speed, accuracy, and reliability that human labour simply cannot provide. The solution is clear: the OSCAM P12-96 mesh bender. This hydraulic powerhouse is more than just a machine; it is a strategic investment in productivity and profitability.

Why the OSCAM P12-96 is a game-changer:

- Boosts speed and output: With its automatic, hydraulic system, the P12-96 can process mesh up to 12mm in diameter across a 4-meter working width. It creates complete polygonal mesh cages in a fraction of the time it takes manual labourers, drastically reducing production timelines.

- Ensures flawless, repeatable precision: Human error leads to inconsistencies and costly material waste. The P12-96, with its electronic programmer, executes pre-programmed bending cycles to the exact angle and dimension every time. This ensures consistent quality across large production runs, minimising scrap and maximising material efficiency.

- Expands fabrication capabilities: The adjustable arm on the P12-96 allows for variable bending radii, enabling the creation of complex, specialised reinforcing elements for slabs, walls, and columns. This versatility allows businesses to bid on and execute more complex, higher-value projects.

- Slashes operational and labour costs: Automating the mesh bending process reduces the physical labour required, freeing up skilled workers for more complex tasks. It also significantly lowers the risk of injury from manual handling and repetitive strain, improving workplace safety and reducing workers’ compensation claims.

- Provides a fast return on investment: For businesses like Australia’s Padman Group, investing in an OSCAM machine was a clear decision to enhance production and meet growing demand. The increased output, reduced material waste, and lower labour costs ensure that the P12-96 quickly pays for itself, providing a competitive edge in the market.

The OSCAM P12-96 isn’t just an upgrade; it’s an evolution for your fabrication process. It’s the difference between a high-volume, precision-driven operation and one limited by time, inconsistency, and manual effort. For companies ready to scale and outperform the competition, the need for this machine is not an option – it’s a necessity.

![HANNSA - Heavy Duty CNC Lathe [Box Ways on 2 Axes - YTH 10E] HANNSA - Heavy Duty CNC Lathe [Box Ways on 2 Axes - YTH 10E]](https://www.delahenty.com.au/newwp/wp-content/uploads/2021/07/hannsa-yth-10e-cnc-lathes-1024x1024.jpg)

![HANNSA - CNC Lathe [Linear Way Series - YTL 8540 / 8540M] HANNSA - CNC Lathe [Linear Way Series - YTL 8540 / 8540M]](https://www.delahenty.com.au/newwp/wp-content/uploads/2021/08/hannsa-ylt-8540-cnc-lathe-linear-way-series.jpg)

![HANNSA - Heavy Duty CNC Lathe [Box Ways On 2 Axes - YTH] HANNSA - Heavy Duty CNC Lathe [Box Ways On 2 Axes - YTH]](https://www.delahenty.com.au/newwp/wp-content/uploads/2021/08/YTH-twin-1024x890.jpg)

![MACKMA - BM48 - Rotary Draw Bending Machine [NOW $19,500+GST] MACKMA - BM48 - Rotary Draw Bending Machine [NOW $19,500+GST]](https://www.delahenty.com.au/newwp/wp-content/uploads/2021/07/5875294.o.jpg)