OnRobot – MG10 – Electric Magnetic Gripper – Cobot End of Arm

Sale!Original price was: $4,100.00.$1,907.00Current price is: $1,907.00.

View BrochureSpecifications

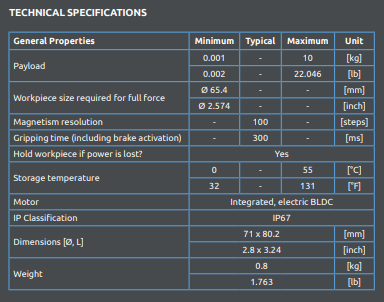

| Make | OnRobot |

|---|---|

| Model | MG10 |

Description

OnRobot – MG10 – Electric Magnetic Gripper – Cobot End of Arm

Demonstration model now $1,907 (1 only)

Delahenty Machinery offers the full range of OnRobot tools include grippers, sensors, tool changers and software that enable small and medium sized manufacturers to automate their processes like never before – quickly, efficiently and cost-effectively.

MG10:

- Electric magnetic gripper offers fast out-of-the-box deployment without the complexity and costs of external air supply

- Built-in intelligence with easily adjustable force and part detection ensures reliable handling of a wide range of part sizes and weights

- Fast, compact and customisable gripper to fit all your application needs

- Ensure safe and reliable operation by maintaining grip even after power loss or emergency stop

- Can be used with products of various sizes and material, including: Metal

Why MG10 Gripper?

OnRobot’s MG10 is a versatile, easy to use magnetic gripper for material handling, assembly and machine tending applications in manufacturing, automotive and aerospace environments. Fully compatible with all major robot brands through OnRobot’s One System Solution, the MG10 offers unique adjustable force and grip detection features that provide users with unprecedented levels of control.

The MG10 advantages and features

With easily configurable magnetic force, the OnRobot MG10 gripper offers adjustable force to ideally match challenging application requirements such as destacking metal sheets one at a time. A built-in proximity sensor detects if a part has been picked up or not, and multi-magnet setups support applications that require reliable handling of large or heavy work pieces. And for safe, collaborative operation, the gripper maintains its hold on work pieces even in the case of power loss or emergency stop.

The affordable MG10 requires no external air supply or cables, for fast, easy installation and no additional costs. Like the rest of OnRobot’s family of no-fuss, all-electric grippers, the MG10 uses the Quick Changer and OnRobot’s intuitive programming for fast easy setup.

MG10 is ideal for unusually shaped parts as well as large flat metal sheets. Unlike vacuum grippers, the OnRobot magnetic gripper leaves no marks and can handle perforated, abrasive, or dusty work pieces. In press-tending and bending applications, the MG10 can manage a part throughout the entire process, even as the part changes shape.

RELIABLE GRIPPING WITH VARIABLE FORCE

The magnetic force can be easily configured in steps to fit your application requirements, even the most challenging like destacking thin metal sheets.

BUILT-IN PART DETECTION

Built-in proximity sensor can detect part presence, as well as if part is pickep up or not.

SAFE CONSISTENT GRIP EVEN AFTER POWER LOSS

If the power is lost, the MG10 gripper will keep the magnetic force and will not drop the workpiece.

NO COMPRESSED AIR REQUIRED

Electric magnetic gripper that is ready to use our of the box, with fast and easy installation and no additional costs.

Collaborative applications are the future of automation, enabling rapid deployment, easy changeovers, and safe operation alongside human workers.

Manufacturers gain true value from innovative collaborative applications that are enabled by a full range of Plug & Produce grippers, sensors, vision, and the software that drives them.

You may also like…

-

OnRobot – RG2 – Flexible 2 Finger Robot Gripper with Wide Stroke

-

Sale!

ONROBOT- RG6- 2 Finger Gripper for Multiple Purposes

Original price was: $8,550.00.$3,954.00Current price is: $3,954.00. -

Sale!

OnRobot – 3FG15 – Flexible, Large-Stroke 3-Finger Gripper

Original price was: $7,650.00.$3,488.00Current price is: $3,488.00. -

Sale!

OnRobot – Dual Quick Changer 4.5A

Original price was: $3,100.00.$1,450.00Current price is: $1,450.00.

![MACKMA – BM60 – Rotary Draw Bending Machine [NOW $22,000+GST] In-Stock List](https://www.delahenty.com.au/newwp/wp-content/uploads/2021/08/2024-11-Mackma-BM60-300x300.jpg)