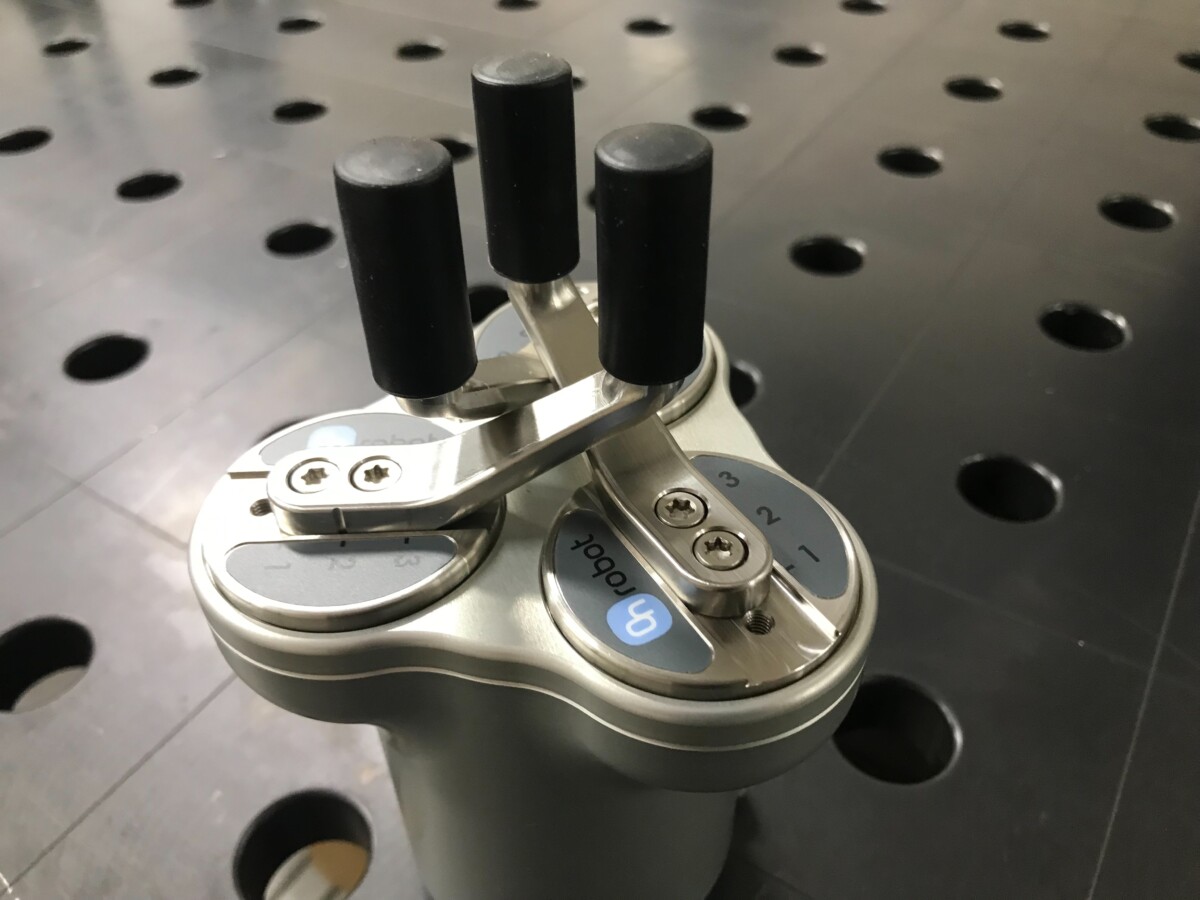

OnRobot – 3FG15 – Flexible, Large-Stroke 3-Finger Gripper

Sale!Specifications

| Make | OnRobot |

|---|---|

| Model | 3FG15 |

Description

OnRobot – 3FG15 – Flexible, Large-Stroke 3-Finger Gripper

Demonstration model now $3,488 (1 only)

Delahenty Machinery offers the full range of OnRobot tools include grippers, sensors, tool changers and software that enable small and medium sized manufacturers to automate their processes like never before – quickly, efficiently and cost-effectively.

FLEXIBLE, LARGE-STROKE 3-FINGER GRIPPER

- Flexible production – large-stroke optimises CNC lathe-tending for multiple part sizes with a single 3-finger gripper.

- Accurate centric positioning drives higher quality, consistency, and output with minimal programming.

- Strong, stable grip with 3 contact points makes the gripper fast and easy to redeploy for multiple processes.

- Accomplish more with customisable fingertips to flexibly grip a wide range of part sizes and shapes.

Why 3FG15 three-finger gripper?

- The 3FG15 is ideal for gripping a wide range of cylindrical objects in machine-tending applications such as CNC lathe machines.

- The gripper’s design automatically centers workpieces, resulting in fast deployment with a strong, stable grip and precise placement.

- With a payload of up to 15kg, the 3FG15 competes with larger, bulkier, and much less flexible finger grippers.

- Like all OnRobot grippers, the 3FG15 offers seamless integration with the robots of your choice.

The 3FG15’s advantages and features

- The 3FG15 three-finger gripper has an impressive maximum stroke of 150mm and a sleek design that can easily handle multiple processes.

- It is ideal for gripping a wide range of cylindrical objects from 20mm to 150mm wide in machine-tending applications such as CNC lathe machines, insertion applications, and even palletising.

- The 3FG15 provides a strong, stable grip for both form fit (inside the object) or friction fit (external) gripping, adding flexibility to your implementation.

- The gripper’s design automatically centers workpieces, resulting in a strong, stable grip and precise placement in machine chucks.

- With a payload of up to 15kg and gripping force from 10 N to 240 N, the 3FG15 competes with larger, bulkier, and much less flexible finger grippers.

PRECISE, STABLE GRIP

Strong, stable grip with 3 contact points makes the gripper fast and easy to redeploy for multiple processes.

LARGE STROKE, UP TO 150MM

Impressive maximum stroke of 150mm and a sleek design that can easily handle multiple processes.

HIGH PAYLOAD, UP TO 15KG

The gripper can lift up to 15 kg making it compatible with cobots with a higher payload.

GRIPPING FORCE 10-240N

Strong, impressive, stable grip up to 240N.

EASY DEPLOYMENT

The gripper comes with pre-integrated software that is easy to install and program, so even employees with no technical background can set it up.

CUSTOMISABLE FINGERTIPS

The fingertips of the gripper can be customised.

Collaborative applications are the future of automation, enabling rapid deployment, easy changeovers, and safe operation alongside human workers.

Manufacturers gain true value from innovative collaborative applications that are enabled by a full range of Plug & Produce grippers, sensors, vision, and the software that drives them.

You may also like…

-

Sale!

ONROBOT- RG6- 2 Finger Gripper for Multiple Purposes

Original price was: $8,550.00.$3,954.00Current price is: $3,954.00. -

OnRobot – VG10 – Vacuum Gripper

-

Sale!

OnRobot – MG10 – Electric Magnetic Gripper – Cobot End of Arm

Original price was: $4,100.00.$1,907.00Current price is: $1,907.00. -

OnRobot – RG2 – Flexible 2 Finger Robot Gripper with Wide Stroke