OSCAM – Fixed-arm & Adjustable-arm Mesh Bending Machine Range

Specifications

| Make | OSCAM |

|---|

Description

OSCAM – Fixed-arm & Adjustable-arm Mesh Bending Machine Range

- The mesh bending machines create complete polygonal mesh cages in a few seconds, thus reducing manual labor.

- The fastest way to create slabs, columns, walls, and more.

- The mesh bending machines are suitable to be used by preshape, but also precast companies who appreciate the speed and ease of manufacturing the reinforcing elements required.

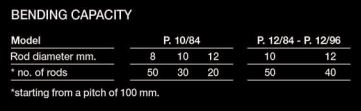

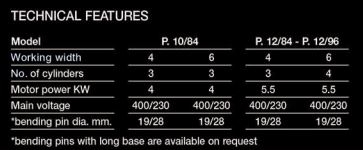

Mod. P10/84 and P12/84

- Machine for bending electro-welded mesh panels (maximum diameter of the wire 10 or 12 mm) and create polygonal cages in a few seconds.

Mod. P12/96

- An adjustable arm version allows both are bending the shorter sides and vary the bending radius according to the pins used.

- All models are available in standard usable lengths of 4 and 6 m (special lengths are available upon request).

Speed Control: Allows The Bending Speed Adjustment

Available Optional: Easy Angle Minicomputer

- The electronic programmer Easy Angle to manage the bending cycle on bending machines and mesh bending machines.

- It can be connected to a barcode reader or to a serial port to import working data (bending angles and number of pieces to produce)

- It is possible to schedule the bending sequence of the main processed shapes and any desired shape.

Equipped with:

- Counter cycle of the produced pieces with an automatic stopping system at the end of the scheduled production

- Auto-diagnostic system visualized on the display that shows possible anomalies

- Possibility to adjust the angles without changing the set values up to +/- 9°. Particularly suitable when you have to process different types of iron.

It can be used on mesh bending machines, combined cutting/bending machines, and bending machines.

- For the bending of welded mesh up to diameter 12 mm

- Motor power: 5.5 Kw

- Voltage: 415/50 Htz AC three-phase, 50 Hz

- Hydraulic system with 4 cylinders

- Pins along the complete working width: according to the number of fabric meshes

- The machine is supplied with bending pins Ø 19 mm.

- The electronic programmer EASY ANGLE is provided with a keyboard to store up to 32 bending angles.

- The angles must be set in the exact sequence in which they must be processed.

- The programmer operates by means of a remote pedal, so that it is possible to obtain the angle visualised on the display

- The memory can contain up to 59 memorised shapes, which can be chosen by means of the keyboard.

Max bending capacity

- bar Ø 8 mm (angle up to 100°) 60 Bars

- bar Ø 10 mm (angle up to 100°) 40 Bars

- bar Ø 12 mm (angle up to 100°) 30 Bars

Read about other companies that have bought similar Oscam bending machines.

![OSCAM – Rod Bending Machine – Model L2 [Made in Italy] OSCAM - Rod Bending Machine - Model L2 [Made in Italy]](https://www.delahenty.com.au/newwp/wp-content/uploads/2022/03/OSCAM-Rod-Bending-Machine-L2-type-1-1-300x300.jpg)