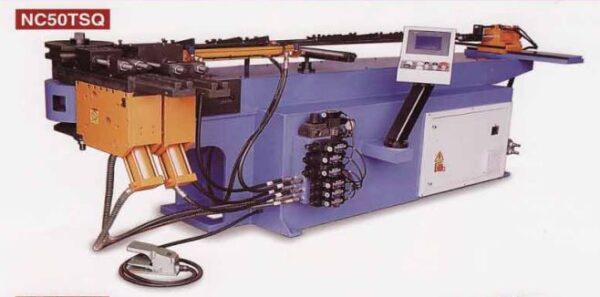

YLM – NC-50 – NC Tube Pipe Bender

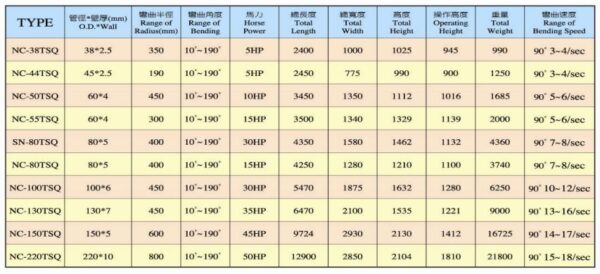

Specifications

| Make | YLM |

|---|---|

| Model | NC 50 |

Description

YLM – NC-50 – NC Tube Pipe Bender

NC 50TSQ Specifications

- Capacity – Carbon Steel 60 mm X 4mm Wall

- Maximum CLR – 450mm

- Total Length – 6100mm.

- Bending speed for 90 degrees – 5 to 6 Secs

- Motor Power – 10hp

- Weight – 3000 Kg.

NC Touch Screen Features

- 6″ display touch screen simplifies the machine operation and function selection.

- Controlled by high efficient PLC base, can store up to 10 length stop and bend angle settings

- Bending motion is sensed and calculated by Japanese made micro encoder, the angle tolerance is ±0.1.

- The pressure die is used to support the bending motion and has the repeat forwarding and retraction function to minimize the die length.

- The computer system can automatically detect and pinpoint malfunctioning sources and allow an operator to inspect or correct problems.

- Utilising the ssr control system, the bending machine is more stable and efficient.

- 2 step mandrel retraction to produce and perfect finished product.

- Based on the dimension and thickness of the working tube, the operator can set delayed timing after each motion.

- All programmed data and bending sequence can be saved and stored for over 3 years. Installing an additional battery may prolong the data storage time