YLM – NC-38 – NC Tube Pipe Bender

Specifications

| Make | YLM |

|---|---|

| Model | NC-38 |

Description

YLM – NC-38 – NC Tube Pipe Bender

- The computer system can automatically detect shortly malfunctioning point to allow operator to solve problems.

- The machine with solenoid valve and integrated circuit to control individual bending motion separately, which also extend the lifetime of the hydraulic parts.

- Three steps hydraulic oil flow for better coding and precipitation to prevent oil deterioration.

- Large model bending machine is equipped with manual hydraulic adjusting valve to control the speed of bending motion.

- Bending motion is controlled by low speed positioning device to obtain the accuracy of bending angles.

- Various angles can be programmed to work multiple bending sequence.

- Eliminating tube material feeding / loading time.

- Both manual and automatic operation are available and all machines are equipped with emergency stop device.

- The main shaft is specially heat treated.

Features:

- One axis numerical controlled of bending-axis by encoder / hydraulic valves

- Bending angle controlled by micro encoder, provides ± 0.1 tolerance

- Mitsubishi PLC ( Programmable Logic Control ) system

- Provides 200 programs memory, each program with 20 angles (bends)

- Provides anticipated two steps mandrel retraction

- Provides pressure die booster

- Provides pressure die micro adjustment of backward to protect the ball mandrel.

- Provides pressure die repetition

- Bending movement time can be programmable to meet different demands.

- 6” display touch screen to operate the machine easily

- Emergency stop of two safety plates with bending arm for working safety

Bending Tooling & Accessories:

- Bending die

- Clamping die

- Pressure die / guide die

- Mandrel (bullet shape)

- 6 pieces of stoppers for tube length control

- A working table for tube rotation fixtures (standard size)

- Wiper die rack

- Ball mandrel / multiple-direction ball mandrel (optional)

- Wiper die (optional)

- Split bending die (optional)

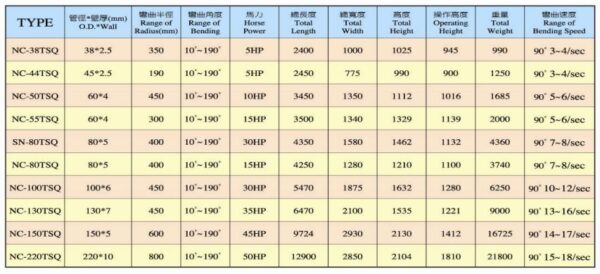

CAPACITY CHART

The most comprehensive range of machines and applicable industries

SPECIFICATION

Machine Name NC 38TSQ

Max. O.D. Wall (mm) 38*2.5

Range of CLR (°) 10~350

Range of Bending (°) 0~210

Mandrel Length (mm) 1750

Operating Height (mm) 960

Horse Power (hp) 5,00

Length (mm) 2400

Width (mm) 700

Height (mm) 1000

Weight (kgs) 900

Range of Bending Speed (mm/sec) 90 3~4 /sec

Angle (°) 20