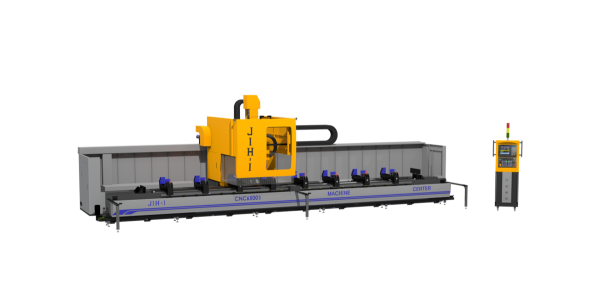

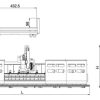

JIH-CNC6500 S Type CNC 3 & 4 Axis Machining Centre

Specifications

| Make | JIH |

|---|---|

| Model | CNC6500 |

Description

JIH-CNC6500 S Type CNC 3 & 4 Axis Machining Centre

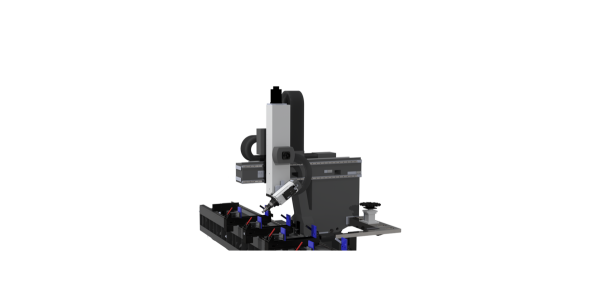

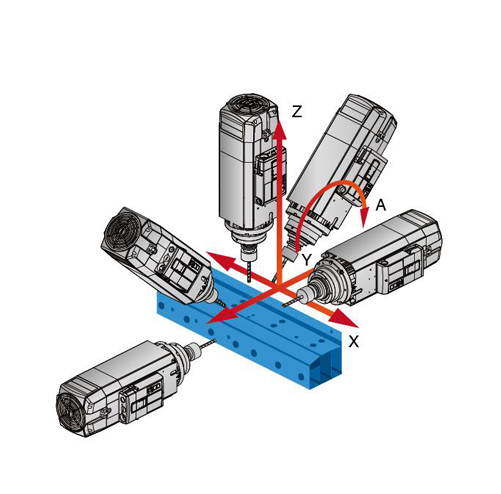

4 Axes Rotary Spindle

- The angular head can be swiveled to 90° rightward and leftward, making it suitable for angular drilling and tapping operations. Also, suitable for face milling and multi-surface machining in one setup.

- Swiveling degree is adjusted through computer control. Minimum indexing angle is:1°.

- A tool clamp/release button is provided on the angular head.

- Integrated type spindle features high accuracy, low vibration, low noise and no backlash.

Machine Features

- The spindle head can be tilting Axis : ±±90゚. It‘s suitable for angular milling, drilling and tapping operations. (Front and Back)

- Tilting degree through computer control.

- A tool clamp / release button is provided on the angular head.

- Integrated-type spindle features high accuracy.

- Specifically for aluminum material, POM, light alloy cutting, drilling, slotting, machining.

- Tempering treatment heavy base keep strong and accuracy.

- German CAM software and vise automatic positioning function, make the 4 axis machining process more simple.

- Choice of X-axis travels: 3,500/4,500/5,500/6,500mm.

- Table type: vise

- ISO 30 spindle speed: 18,000 RPM

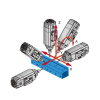

- 8-tools disk type magazine.(Opt. 12 tools)

- Traveling column design features increased machining efficiency and accuracy.

- Three axes are equipped with high precision linear guide ways.

- Y&Z axes ball screws are directly coupled with servo motors.

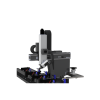

- Syntec controllers-PC-based.

- Fully enclosed splash guard (optional).

Applicable Materials

- Aluminum

- Other non-ferrous metals

Applicable Industries

|

| Model | 6500S | 3500S |

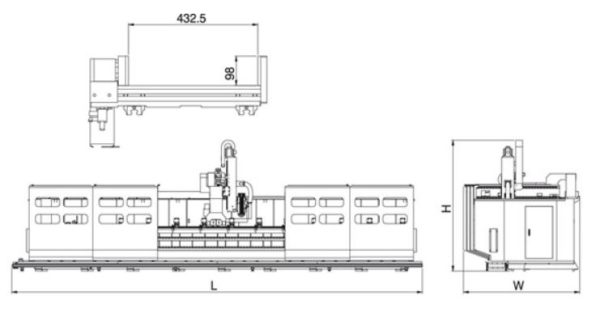

| LxWxH | 9,000×2,550×3,200mm | 6,000×2,550×3,200mm |

| Table | 6,500x375mm | 3,500x375mm |

- Multi-Machining for Short Work Pieces: For machining short work pieces, the operator may mount the work pieces on the table to machine simultaneously.

- Extra Long Work Piece Machining: This machine is excellent for machining extra-long work pieces with only one setup. Suitable machining includes milling, drilling and tapping. With such machining nodes, you can save considerable time.

- Different Parts Machining: With this mode of machining, greater efficiency can be obtained.

- SYNTEC controller – PC-Base CNC Controller: Machines are equipped with Syntec PC-Base CNC controller, featuring easy to learn and easy to operate.

- Laser Interferometer: After each machine has been assembled, our experienced personnel applies a laser interferometer to inspect and calibrate ball screw pitch error and backlash, positioning accuracy, as well as repeatability on the X, Y and Z-axes. Through the laser inspection process, we can guarantee high feed accuracy on three axes as well as overall machining accuracy.

- Ball Bar Test: To assure the highest structural mechanical assembly accuracy, and to eliminate the reverse spike phenomenon, all Bar tested during the assembly processes. The test will calibrate the machine to the optimum status, thus extends the life time of axial ball screw and slideways.

- Oil Mist Cooling: The machine is equipped with an oil mist cooling system for efficient cooling of cutting tool and work piece. It not only extends the service life of the tool, but also ensures superior cutting quality.

- Automatic Lubricator: All linear guide ways and ball screws are automatically lubricated by an erasures lubricator. It keeps all axes move smoothly.

Product Specification

| Model | JIH-CNC S3 (3Axis) | JIH-CNC S4 (4Axis) |

|---|---|---|

| Stroke | ||

| X-Axis Stroke | 3,500/4,500/5,500/6,500mm (Opt.) | 3,500/4,500/5,500/6,500mm(Opt.) |

| Y-Axis Stroke | 450 mm | 450 mm (A0°) / 200 mm (4 Axis) / A+90° A-90° |

| Z-Axis Stroke | 500 mm | 500 mm |

| Table | ||

| Table Type | vise (1 set/per meter) | vise (1 set / per meter) |

| Table Size | 432 x 3,500-6,500mm | 432 x 3,500-6,500mm |

| Table Heigh From Floor | 950 mm | 950 mm |

| Spindle | ||

| Spindle Speed | 18,000R.P.M. | 18,000R.P.M. |

| Spindle Motor | 10HP (7.5kw) | 10HP (7.5kw) |

| Spindle Taper Cone | ISO 30 | ISO 30 |

| Sawblade size | 10″x1″ Bore (with 90° angular head) | 10″x1″ Bore (with 90° angular head) |

| Feed Rate | ||

| Rapid Feed Rate(X/Y/Z) | X:50 m/min, (Opt. 80 m/min) Y:24 m/min, Z:24m/min | X:50 m/min, (Opt. 70m/min) Y:24 m/min, Z:24 m/min |

| Servo motors of 3 axes | X:2kw , Y:1kw , Z:2kw | X:2kw , Y:1kw , Z:2kw, A:750w |

| Cutting feed rate | F:1-5,000 mm/min | F:1-5,000 mm/min |

| ATC | ||

| Magazine Capacity | 8 Tools(Opt. 12 tools) | 8 Tools(Opt. 12 tools) |

| Tool Holder | ISO 30 | ISO 30 |

| Dimensions | ||

| Required Pneumatic Pressure | 6 kgs/cm2 | 6 kgs/cm2 |

| Machine Dimensions | 6,000-9,000 x 2,500 x 3,200 mm | 6,000-9,000 x 2,500 x 3,200 mm |

| Packing Dimensions | 6,100-9,100 x 2,300 x 2,450 mm | 6,100-9,100 x 2,300 x 2,450 mm |

| Machine Weight | 4,500-6,500 kgs | 4,500-6,500 kgs |