IMET – Automatic Double Column Bandsaw – model: XSMART4

Specifications

| Make | IMET |

|---|---|

| Model | XSMART4 |

Description

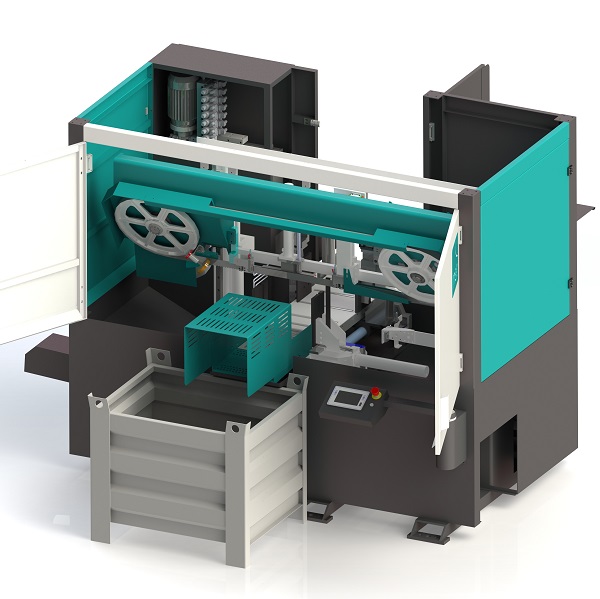

IMET – XSMART4 – Automatic Double Column Bandsaw

Automatic double-column bandsaw for solids

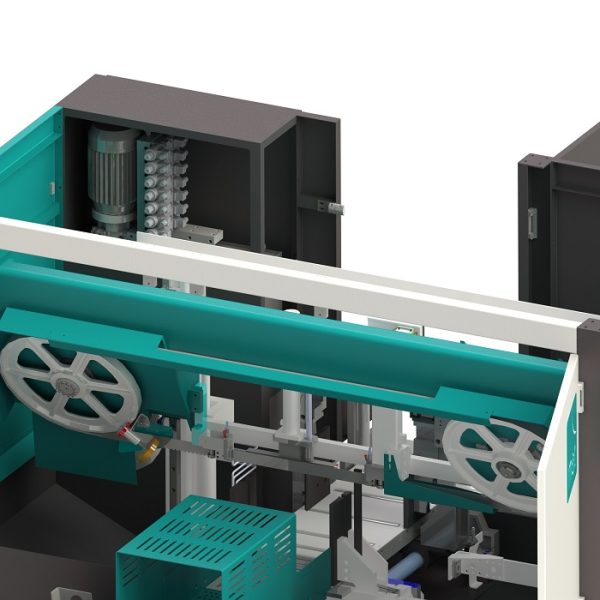

XSMART4 is n automatic double column bandsaw suitable for straight cut of solids up to 360mm diameter, the ideal working tool for professionals and workshops who look for the best efficiency and productivity on an easy-to-use and affordable machine. XSMART4 is equipped with a 4 kW motor reducer, a blade height 41mm, 7″ touch screen display and an integrated feeder.

TECHNICAL INFORMATION

| Cutting capacity at 0° | Round 360mm Square 360mm Rectangular 360x360mm |

| Cutting capacity with solids (C45) | 350mm |

| Cutting capacity with bundle device | Max 360x250mm Min 130x10mm Minimum scrap-end 210mm |

| Minimum cutting length | 10mm |

| Minimum scrap-end | 100mm (in option 40mm) |

| Blade size | 5050x41x1.3mm |

| Blade inclination | 0° |

| Blade motor power | 4 KW |

| Blade speed | 15-100 m/min |

| Feeder length and single stroke | 500 mm |

| Feeder motor power | 0.75 KW |

| Hydraulic unit motor | 2.2 KW |

| Hdraulic unit tank capacity | 54 l |

| Coolant tank capacity | 130 l |

| Size – working table height – Weight | 3000x2600x2200mm 890mm 2800kg |

User safety and easy maintenance: XSMART4 bandsaw gives the user maximum protection and safety while in use, thanks to the full metal carters system that protects all the moving parts and two tunnels on loading and unloading that prevent access (while in action) to the cutting area. Once the machine is put in stand-by, the operator can easily access to all the internal components thanks to the big frontal, lateral and back doors.

Touch screen display: XSMART4 is equipped with a 7″ touch screen display with an easy and intuitive interface: the display gives full control on all the main machine settings (like manual movement of XSMART axes) and allows to easy creation of cutting programs and launch a working cycle with just a few clicks. The down feed speed view (in mm/min) is supplied as standard.

Sawframe: XSMART3 sawframe has an electro-welded rigid structure on a double column, which helps reduce vibrations and binding during descent. Like many IMET bandsaws, its blade is canted (30°) to reduce the band strain and have better and constant sawframe descent while cutting with optimised performances on every material, profiles or solid.

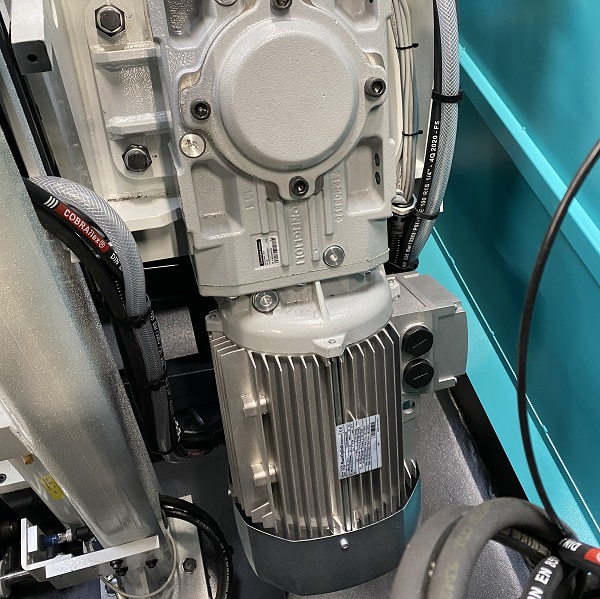

High power motor reducer: XSMART4 uses a high power, high efficiency and reliable Bonfiglioli motor reducer by 4 kW for its blade, which has 41 mm height with a hydraulic tensioning system.

Integrated feeder: XSMART feeder has a single stroke of 500mm with an integrated roller table for material support. The feeder moves with a recirculation screw and electric motor with an inverter, a portal structure that eases material movement and loading.

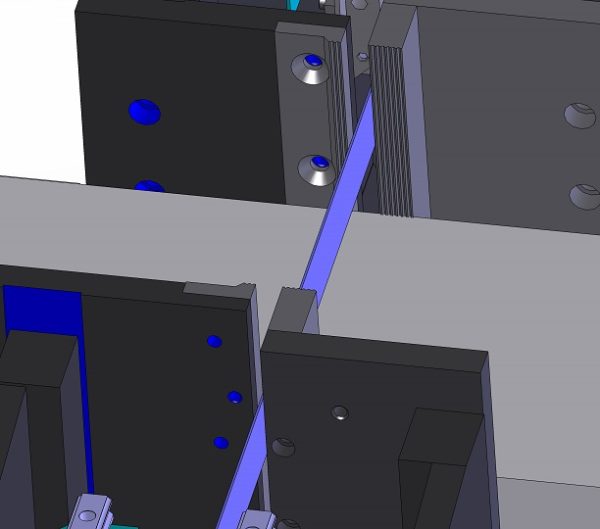

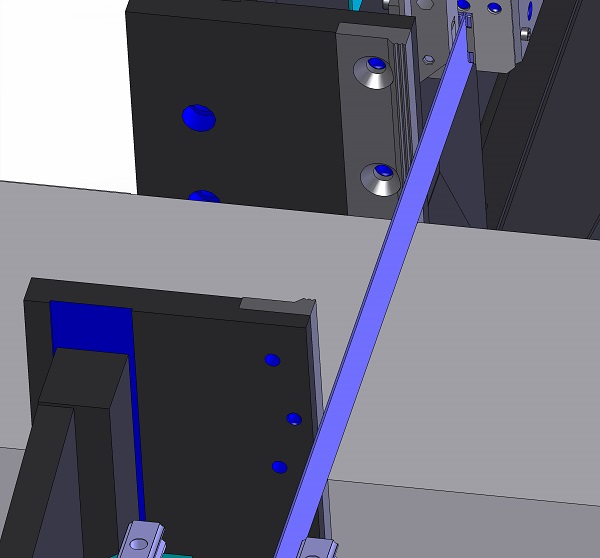

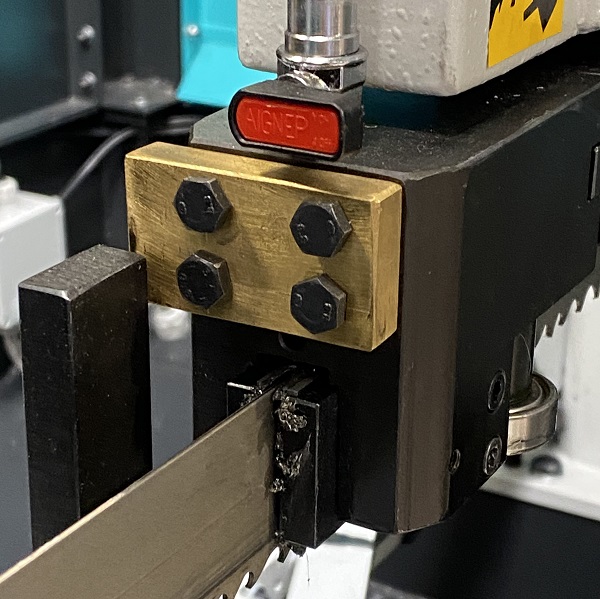

Vice: Blocking vice provides for the perfect material locking and is equipped with an innovative system that allows for opening all 4 jaws independently; this helps to load even non-rectilinear bars. The user can choose between two main configurations for the vice: 4 jaws (2 placed before the blade and 2 after) or with 2 jaws placed only after the blade.

Vice 4 jaws (2 before the blade and 2 after): This configuration presents 4 jaws: 2 lock the material before the blade and 2 after the cut. We strongly ma suggest this configuration in case the user wants to use a hard metal blade (WIDIA) so that the stability is increased during the cutting process. Minimum scrap end: 100mm.

Vice 2 jaws: The user can select this configuration with 2 jaws on the vice placed only after the blade so that the material is locked only after the cut line. This configuration allows for reducing the scrap end to just 40mm.

Blade alignment: Hard metal blade guides with bearings to have optimal blade alignment during the cutting process. The mobile blade guide is kept automatically next to the cutting point.

Chips conveyor: XSMART4 mounts a standard chips conveyor with a lateral exit that eases the cutting process by removing (together with a brush on the blade) all the remaining and residual material that lies in the cutting area.