IMET – BS400 SHI – Semiautomatic Bandsaw

Specifications

| Make | IMET |

|---|---|

| Model | BS400 SHI |

Description

IMET – BS400 SHI – semiautomatic bandsaw

Semiautomatic pivotal bandsaw to cut steel

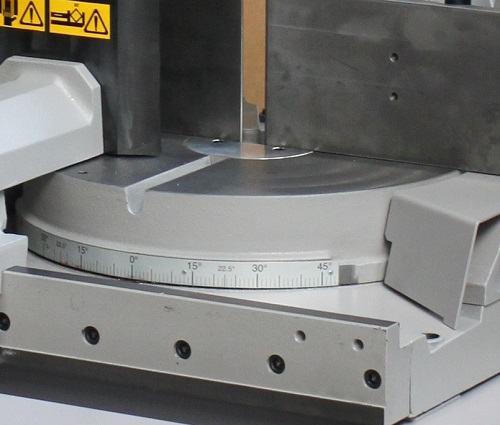

Imet semiautomatic pivotal bandsaw BS 400 SHI is the professional tool suitable for medium sized production of tubes and profiles for carpentry. It’s able to cut up to 45° on the right and 60° on the left. The machine can be used in every working environment and workflow to cut steel (even with high resistance) and cast-iron materials.

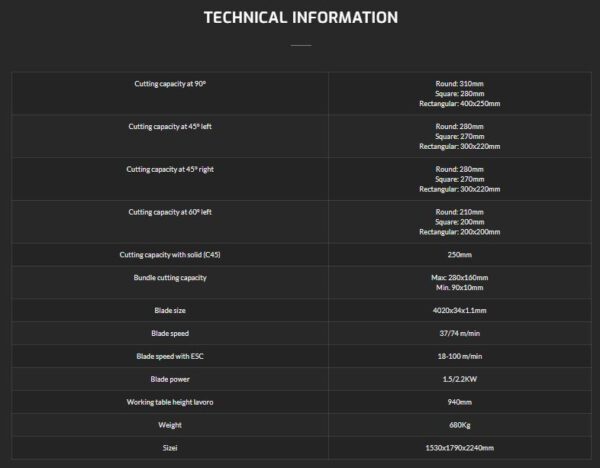

TECHNICAL INFORMATION

| Cutting capacity at 90° | Round: 310mm Square: 280mm Rectangular: 400x250mm |

| Cutting capacity at 45° left | Round: 280mm Square: 270mm Rectangular: 300x220mm |

| Cutting capacity at 45° right | Round: 280mm Square: 270mm Rectangular: 300x220mm |

| Cutting capacity at 60° left | Round: 210mm Square: 200mm Rectangular: 200x200mm |

| Cutting capacity at 0° with solids (C45) | 250mm |

| Bundle cutting capacity | Max: 280x160mm Min. 90x10mm |

| Blade size | 4020x34x1.1mm |

| Blade speed | 37/74 m/min |

| Blade speed with ESC | 18-100 m/min |

| Blade power | 1.5/2.2KW |

| Working table height lavoro | 940mm |

| Weight | 680Kg |

| Sizei | 1530x1790x2240mm |

Working area: BS 400 SHI has a wide working area able to optimize the user workflow: the working table allows to have full support of the material and rotate together with the saw to avoid damages on its surface.

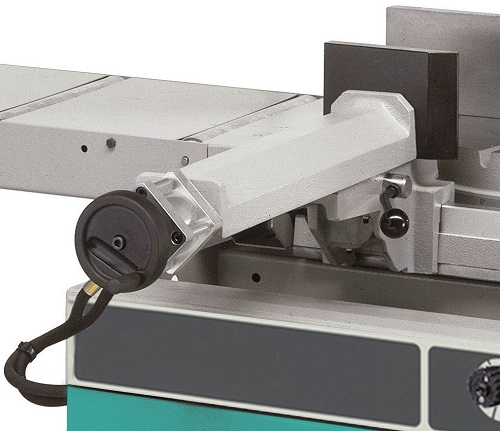

Material detect device: To ease the cutting process and increase the user-experience, the machine is equipped with a mechanic material detect device that automatically detect the material position and first cut point. End cut is processed with a microswitch.

Rigid sawframe: BS 400 SHI bow is made in steel with tubolar section, 360mm pulleys while the blade is protected by metal sheet. A dedicated support piston allows to change the blade easily. The blade is 34 mm height with high tension (2000 kg/cm2) to reduce vibration, breakage and slow-downs while feeding inside the material.

End cut with canted blade: The machines uses an innovative system for the end cut with canted blade to reduce strain on the blade and increase cutting performances. The canted blade ease the process even on solid material, allowing to work on material sections and not on the full solid part.

Motoreducer: BS 400 SHI is equipped with a strong, powerfull motoreducer made in cast-iron.

Hydraulic vice: The vice is hydraulic with sliding guides on the blade with fast approach system.