ONROBOT – Cobot 6-Axis Force Torque Sensors

Specifications

| Make | OnRobot |

|---|---|

| Model | Cobot 6 |

Description

ONROBOT – Cobot 6-Axis Force Torque Sensors

- Flexible sensor extends automation possibilities to processes that weren’t previously possible

- High-accuracy sensor technology provides 95% better quality in insertion and assembly tasks.

- Easy programming gets even complex polishing tasks up and running in less than a day

Why Hex 6-axis Force/torque Sensor?

OnRobot 6-axis force torque sensors provide accurate force and torque measurements along all 6 axes. This gives you precise control when it comes to difficult assembly, polishing, sanding or deburring jobs.

Additionally, the HEX software includes path recording, force control and special features for insertion tasks.

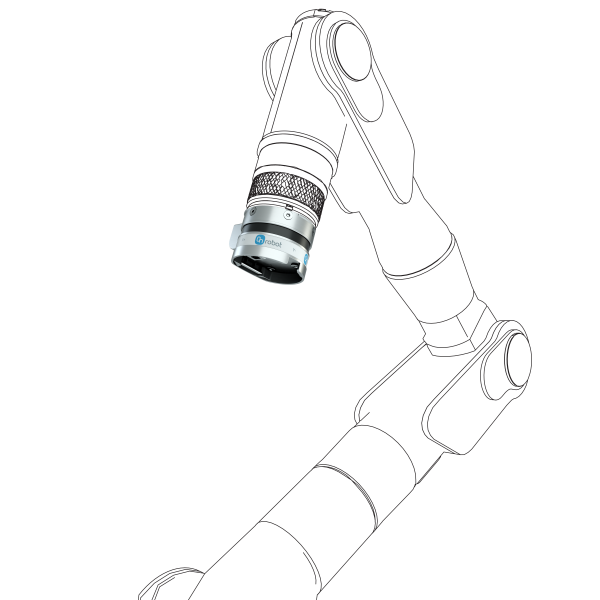

This means reduced integration time for your production line. Our sensors are designed to fit most of the current industrial robot arms. Common applications are polishing, sanding, deburring, grinding and assembly, but it can also be used for teach-in and crash detection.

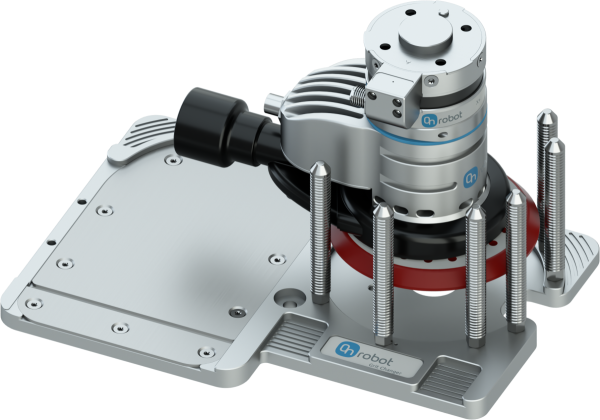

Currently available models: HEX-E /High Precision, HEX-H /Low Deformation, HEX-E QC, HEX-H QC

The HEX force/torque sensor’s advantages and features

Designed to fit all major robot brands, OnRobot’s HEX 6-axis force/torque sensor offers 6 degrees of force and torque measurement.

This makes the HEX 6-axis force/torque sensor perfect for complex sanding, deburring, or assembly operations, as it gives you precise control over your end-of-arm tooling’s applied force.

The sensor is especially ideal for surface finishing tasks, because it ensures a constant speed and force is kept throughout the finishing. The constant force allows the finishing tool to follow the surface contours of the work piece, leading to a flawless result.

Thus, by adding the OnRobot HEX 6-axis force/torque sensor into your production line, you will gain optimization and productivity advantages without compromising the quality of your solutions.

Unique optical based technology: Compared to other technologies the unique OnRobot sensor technology generally much more robust, can resist sudden shocks.

Advanced force control: Keeps constant speed and force while moving

Easy to install graphical user interface, fast programming: You can start your application development within an hour

High accuracy: Precise force/torque measurement on 6 axis ( (Fx,Fy,Fz,Tx,Ty,Tz)

Integrated software: The gripper comes with pre-integrated software that is easy to install and program, so even employees with no technical background can set it up.

Easy hand guiding, path recording: You can record complex paths within minutes

You may also like…

-

Sale!

ONROBOT- RG6- 2 Finger Gripper for Multiple Purposes

Original price was: $8,550.00.$3,954.00Current price is: $3,954.00. -

OnRobot – RG2 – Flexible 2 Finger Robot Gripper with Wide Stroke

-

Sale!

OnRobot – 3FG15 – Flexible, Large-Stroke 3-Finger Gripper

Original price was: $7,650.00.$3,488.00Current price is: $3,488.00. -

Sale!

OnRobot – MG10 – Electric Magnetic Gripper – Cobot End of Arm

Original price was: $4,100.00.$1,907.00Current price is: $1,907.00.