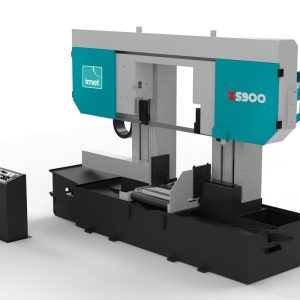

IMET – XT4 – Professional Bandsaw

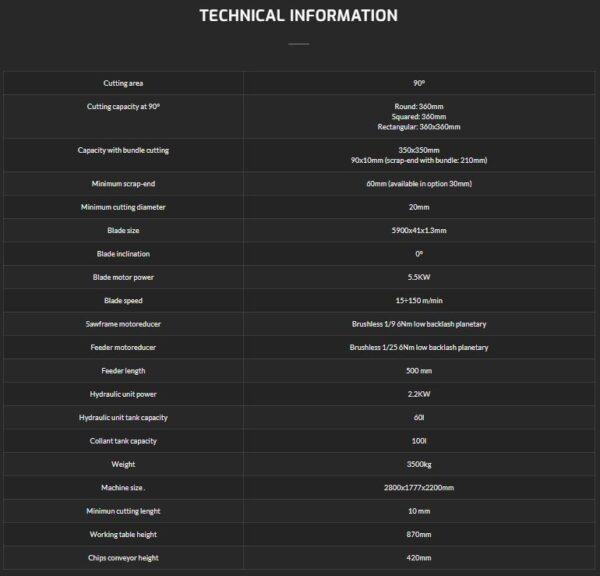

Specifications

| Make | IMET |

|---|---|

| Model | XT4 |

Description

IMET – XT4 – Professional Bandsaw

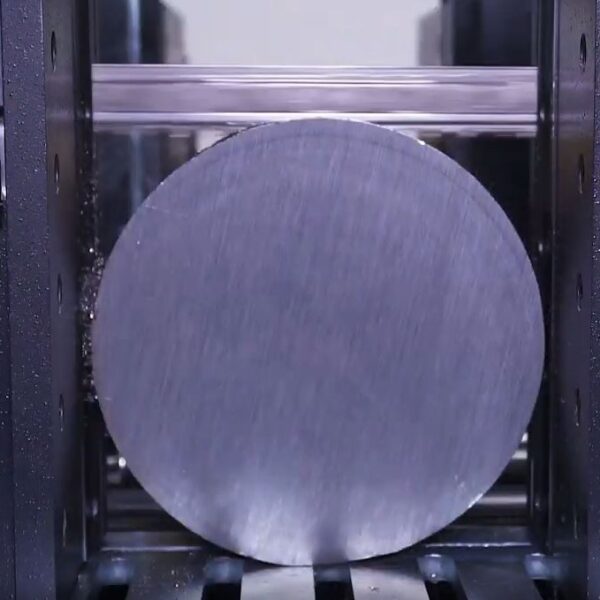

XT Series are the latest and most advanced professional tool developed by IMET technicians for industry application and massive production of steel and metal solids: XT4 is an automatic double column bandsaw with straight cut with automatic cutting parameters, touch screen display, innovative design to guarantee user safety during the entire cutting process

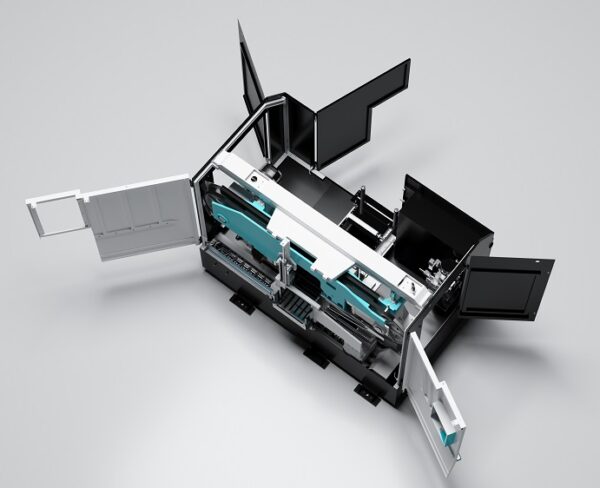

Innovative design

Innovative, fascinating and clean: these are the main features of the XT Series design that have provided these machines to the prestigious ADI (Italy’s association dedicated to the best products of the Italian industrial design) Design Index selection and the publication on the renowned ADI magazine as one of the best products of Italian design. The XT Series was also officially selected to be a contestant for the Golden Compass, the most famous Italian design award.

10″ touch screen display

XT Series uses CNC numeric control to manage all the machine settings. The machine is also equipped with a simple and easy-to-use 10″ touch screen display with a user-friendly and intuitive interface that gives the operator full control on all the machine’s operational parameters, increasing and optimising the user experience, making the machine the ideal working tool in a professional environment for industry applications.

Automatic settings and materials library

Inside the machine it’s has been uploaded a material library with more than 150 materials with preset parameters and cutting settings, fully accessible through the touch screen and the easy-to-use machine interface; the library allows to start cutting even with no experience, the user just need to follow the intuitive instruction: just few clicks to select the material and the cutting program, then XT software will calculate cutting settings to optimize the process and start the production.

User safety

User safety is provided by the new design full-carter system, which covers all the machine’s moving parts while the machine is working so that the user cannot be in danger. In case of the opening of a carter, the machine has a microswitch system that immediately stops the movements. Every working error or breakage is indicated on the display.

Full access

The protection system doesn’t mean it’s not easy to intervene in case of maintenance: all the carters can open up, providing full access to all the internal machine parts. A sump pump provides for the collection tank cleaning.

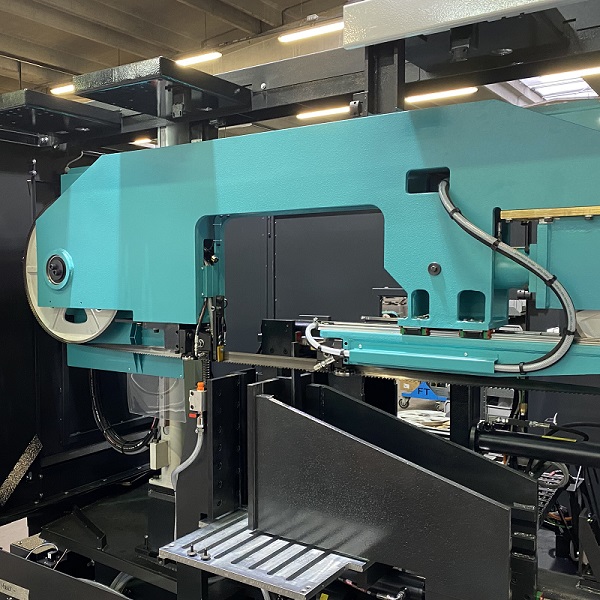

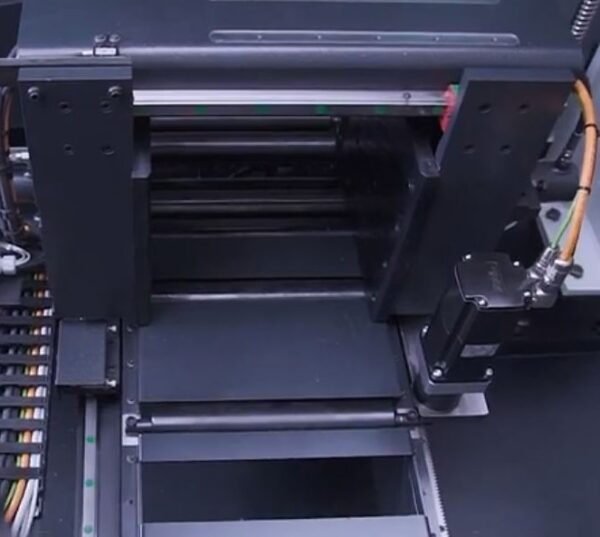

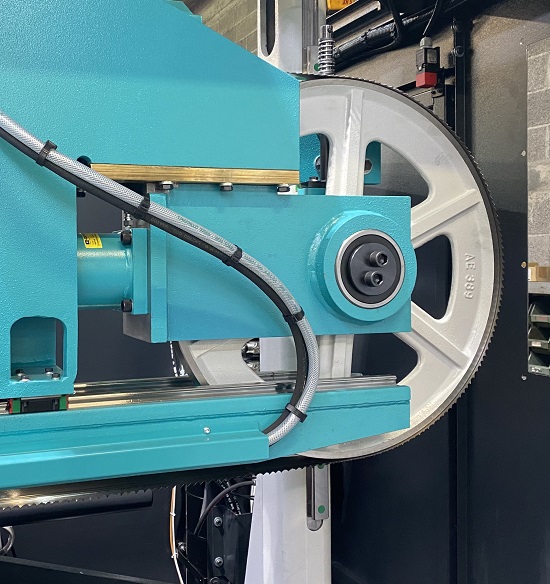

Double structure sawframe

XT Series sawframe has a rigid double structure in electro-welded steel specifically designed to have the highest resistance even on the biggest cutting processes; this massive structure reduces vibrations, bindings and noises while working, optimising performances on all kinds of materials and shapes.

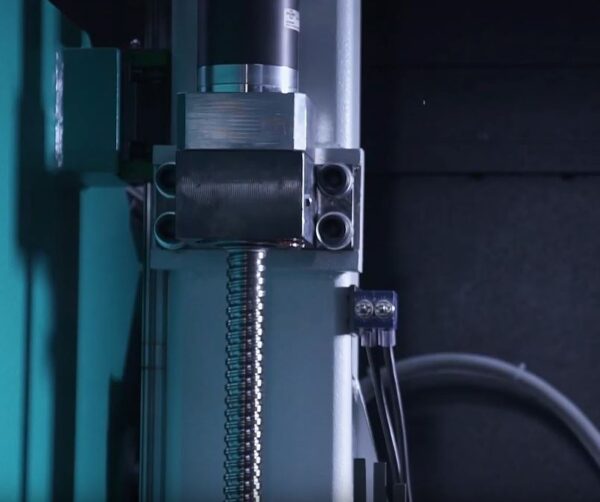

Sawframe movement

Sawframe movement is perfectly balanced and provided by a high-performance brushless low low-backlash planetary gearbox motor with a recirculating ball screw and 6 Nm. Sawframe also slides on two linear guides (one for each side). Thanks to this highly accurate sawframe movement, it’s possible to increase sawframe descent speed control precision with better rates even on lower rates.

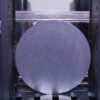

Integrated feeder

The material is placed on the integrated roller table (500mm with stroke repetition, equipped with rack and pinion to ideal position and speed control) and locked by the vice jaws that have the unique feature to open on both sides, so that the feeding process is optimised even on non-rectilinear bars. The feeder has a brushless, low backlash planetary gearbox and slides on rectified guides and recirculating ballscrew runners.

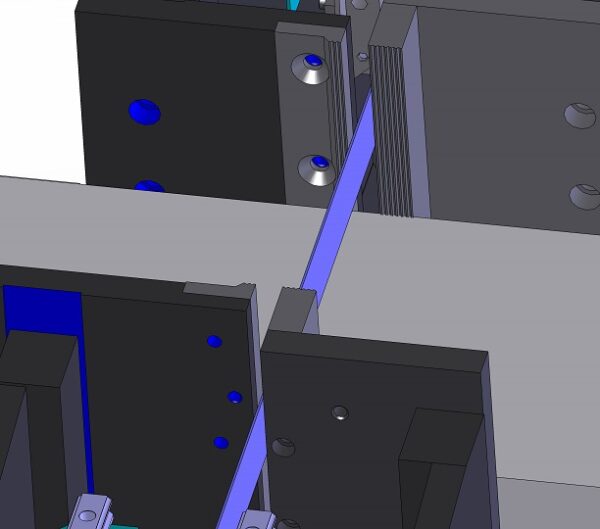

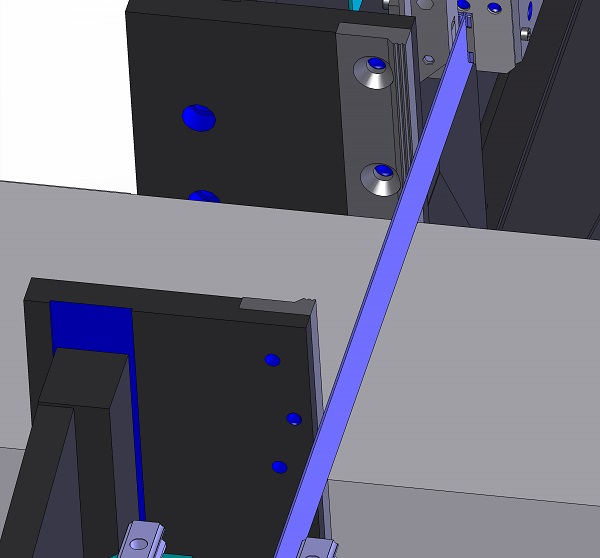

Vice

Blocking vice provides for the perfect material locking and is equipped with an innovative system that allows to open all 4 jaws independently; this helps to load even non-rectilinear bars. The user can choose between two main configurations for the vice: 4 jaws (2 placed before the blade and 2 after) or with 2 jaws placed only after the blade.

Vice: 4 jaws

This configuration presents 4 jaws: 2 lock the material before the blade and 2 after the cut. We strongly suggest this configuration in case the user wants to use a hard metal blade (WIDIA) so that the stability is increased during the cutting process. Minimum scrap end: 60mm.

Vice: 2 jaws

The user can select this configuration with 2 jaws on the vice placed only after the blade, so that the material is locked only after the cut line. This configuration allows for reducing the scrap end to just 30mm.

Pale tension

Hydraulic cylinder driven blade tension is also managed by the bandsaw software. If the machine has been used for some period, the control system provides to release the band (reducing tension) to avoid strain. In case of breakage, the control commands an immediate stop to the process with an alarm on display.

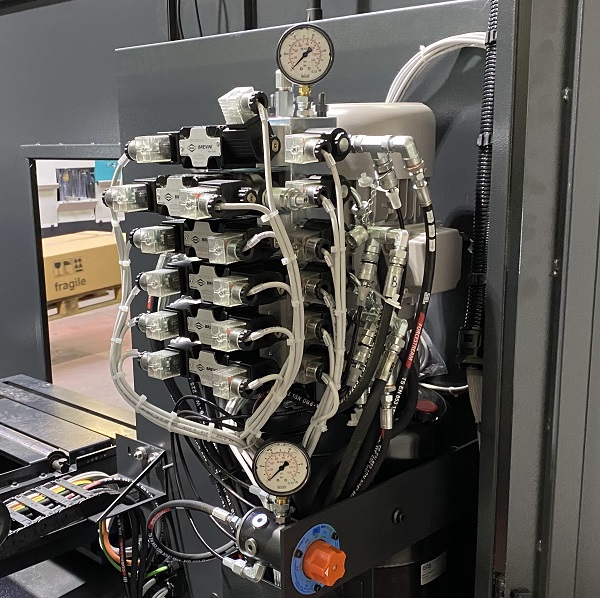

Saving energy

The XT Series innovative hydraulic unit allows for saving 80% of the energy consumption compared to traditional units: our power unit uses 3 kW/h a day while other units’ consumption is 16 kW/h per day. This allows for saving up to 400 euros per year (the data has been calculated on an 8-hour per day functioning, 220 working days per year).

Detach system

Once the cut ends, the feeder backs off, and the system allows the blade to detach from the material before the bow rises. This process helps reduce the friction between the blade and the cut piece and increase the cutting efficiency of your machine, helping to save blade life when using hard metal bands and/or bundle cutting devices.

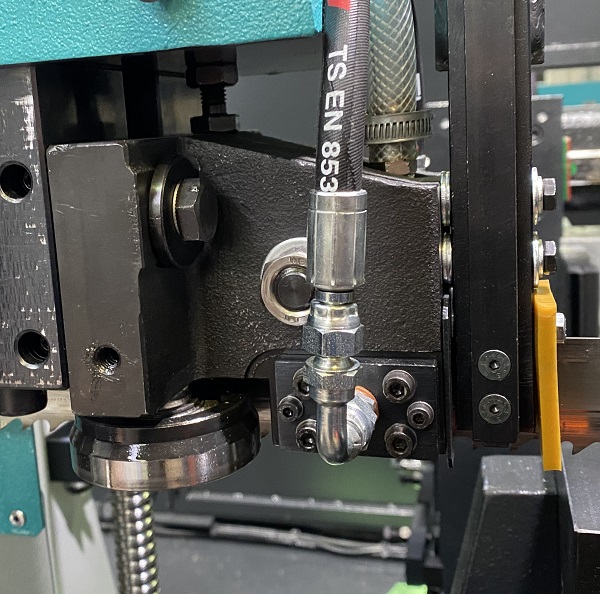

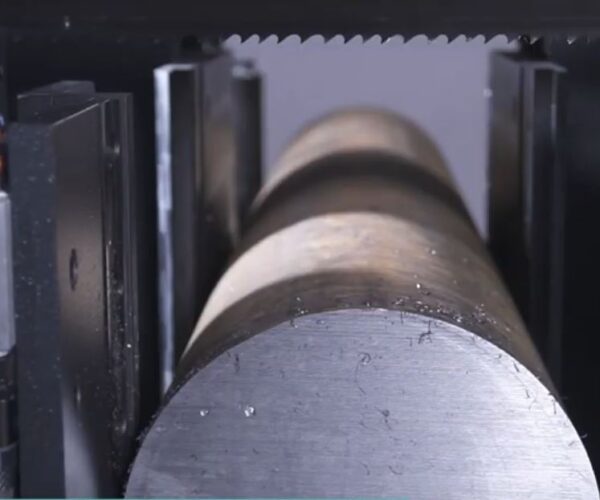

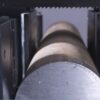

Blade guides

Hard metal pads, blade guides, hydraulically kept in touch with the band; blade guides are equipped with cemented, hardened, rectified lateral guide rolls with easy regulation. Inside the blade guide, there’s a widia-ring bearing leaning on the blade back to provide the best alignment, saving the bearing life.

IMET Sense

IMET Sense allows speeding up cutting times, optimising the band’s fast approach to the material: once the blade comes at 10mm of the piece, the machine uses the faster cutting parameters (added in the material parameters table) that have been applied to that material.

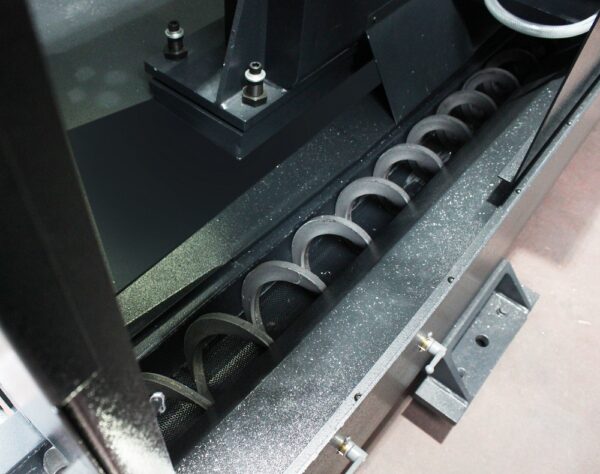

Chip conveyor

XT Series machines are equipped with a standard chip conveyor with 420mm height evacuation

Device features:

- cutting capacity: round up to 360 mm

- hydraulic belt tension

- built-in database of cutting parameters for over 150 types of material

- cutting band dimensions: 5900mm x 41mm x 1.3mm

- belt speed: 15 – 150 m/min (stepless regulation – inverter)

- Operation via a 10-inch touch screen with an intuitive interface

- If the cutting tolerance deviates from the required standards, the machine reduces the cutting speed or stops it completely

- The mechanical components of the machine are protected by covers and allow access for maintenance purposes only

- The machine automatically sets parameters depending on the type of tape and material dimensions

- minimum cutting length 15 mm

- The minimum residual element length in HA and CNC mode is 20 mm

- length of a single feed 500 mm

- maximum feeding length 9000 mm

Standard equipment:

- Cooling system

- Bimetallic tape – 1 piece in the machine

- User manual in English

- CE certificate

Optional equipment:

- Modem compliant with Industry 4.0 standards: teleservice and remote machine operation