YLM – NC-130 – NC Tube Pipe Bender

Specifications

| Make | YLM |

|---|---|

| Model | NC-130 |

Description

YLM – NC-130 – NC tube pipe bender

Features:

- One axis numerical controlled of bending-axis by encoder / hydraulic valves

- Bending angle controlled by micro encoder, provides ± 0.1 tolerance

- Mitsubishi PLC ( Programmable Logic Control ) system

- Provides 200 programs memory, each program with 20 angles (bends)

- Provides anticipated two steps mandrel retraction

- Provides pressure die booster

- Provides pressure die micro adjustment of backward to protect the ball mandrel.

- Provides pressure die repetition

- Bending movement time can be programmable to meet different demands.

- 6” display touch screen to operate the machine easily

- Emergency stop of two safety plates with bending arm for working safety

Bending tooling & Accessories:

- Bending die

- Clamping die

- Pressure die / guide die

- Mandrel (bullet shape)

- 6 pieces of stoppers for tube length control

- A working table for tube rotation fixtures (standard size)

- Wiper die rack

- Ball mandrel / multiple-direction ball mandrel (optional)

- Wiper die (optional)

- Split bending die (optional)

The machine adopting solenoid valve and integrated circuit to control separately, which can be extend the life of the hydraulic parts.

The computer system can automatically detect shortly malfunctioning point to allow operator to solve problems.

We can supply wide range of bending machines capable of bending tube O.D. up to 203 mm (8” diameter). Tube wall thickness up to 10 m/m.

NC tube bender, NC Hydraulic Tube Bender Machine

- Based on the tube diameter, wall thickness and bending radius, machine operator may select to bending application with or without mandrel.

- The bending-die spindle is solid one, will easy have tooling changing, and provides the minimum bending radius 1-1.5 DR.

- We can supply wide range of bending machines capable of bending tube O.D. up to 203 mm (8″ diameter).

Tube wall thickness up to 10 m/m. - Simple to work and user friendly functions allow non-technician and new operator to joint production force rapidly.

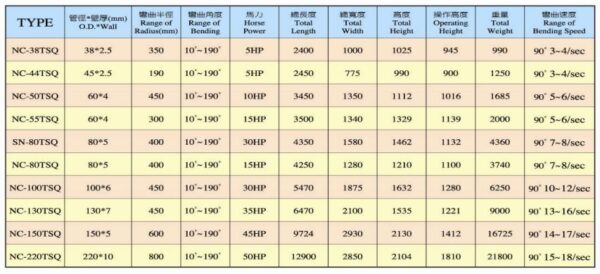

CAPACITY CHART

The most comprehensive range of machines and applicable industries

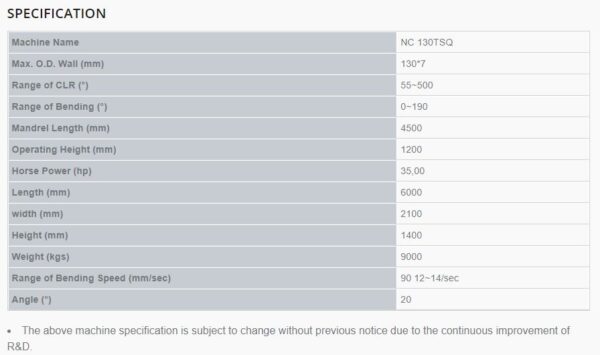

SPECIFICATION

| Machine Name | NC 130TSQ |

|---|---|

| Max. O.D. Wall (mm) | 130*7 |

| Range of CLR (°) | 55~500 |

| Range of Bending (°) | 0~190 |

| Mandrel Length (mm) | 4500 |

| Operating Height (mm) | 1200 |

| Horse Power (hp) | 35,00 |

| Length (mm) | 6000 |

| width (mm) | 2100 |

| Height (mm) | 1400 |

| Weight (kgs) | 9000 |

| Range of Bending Speed (mm/sec) | 90 12~14/sec |

| Angle (°) | 20 |