YLM – CNC Hybrid Tube Bending Machine – CNC-80S1-3A-RHT

Specifications

| Make | YLM |

|---|---|

| Model | CNC-80S1-3A-RHT |

Description

YLM – CNC Hybrid Tube Bending Machine – CNC-80S1-3A-RHT

General Description:

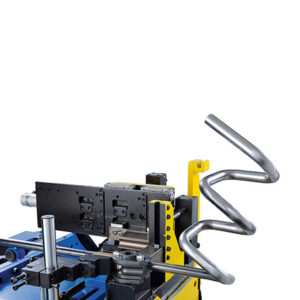

- Fully automatic CNC bending and Rolling machine.

- 3 axis of automatic operation: Hydraulic bending, Servo rotating and Servo feeding

- Proportional controlled manual dial follower slide

- Safety Package including 3 x Safety Mats and Two-handed cycle start.

- Collet Close Button for easy loading

- Quality components: Yaskawa servo motors and encoders, Sunus reducers, Rexroth and Hiwin linear guides

- Yuken hydraulic system from Japan

- Draw bending functions.

- Multiple axes working simultaneously to decrease bending cycle time.

- User friendly program setup- PC base controlled system for ease of upgrading & modifying program.

- Batch work function

- Unlimited program storage with unlimited steps in program

- Single stack tool holders

- Tooling compatible ability (adapter) function

- Oil cooler

- One key back up of programs to disk / USB storage device

- Security code protection of parameters and selected operation features

- Instant diagnosis of error

- Manual step by step teach mode to solve interference problem.

- Access to historic bending data to facilitate study of malfunction.

- Mandrel lubrication System

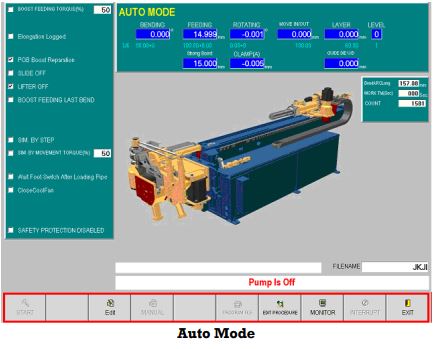

Software:

- Windows operating system

- YLM developed BCB CNC control software/program (as Below)

- Easy YBC setup and AutoCAD /DXF (ver. 2004 and upwards) XYZ coordinates conversion into YBC

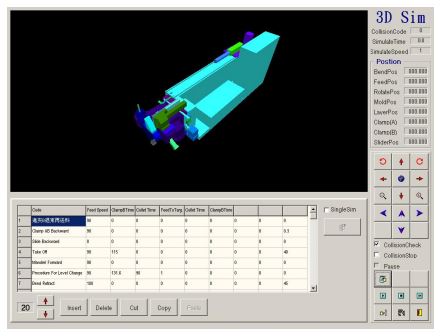

- 3D work piece preview

- 3D animation bending simulation with part interference (as Below)

- Touch Screen Software

- Elongation compensation

- Spring-back compensation

- Unlimited programmability

- Mirror of YBC program

- Tube feeding axis with repetition function ( step-feeding without mandrel to bend with unlimited tube length )

- Repetitions of pressure die movement to operate with minimize length of follower

- Tube recapture function

- On screen Instruction manual

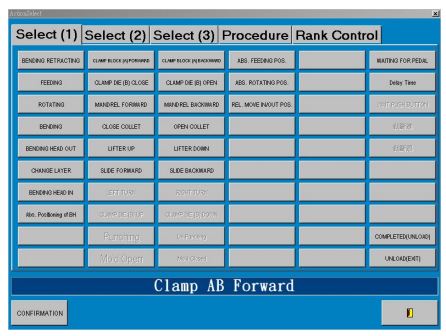

- Part Editor (as pictured)

- 10 speed selection for each axis programmed per line.

- Flexible selection of Manual, single bend, Semi-automatic and automatic modes

- Single bending with feed supporting bend function of Colle.t

- Part counter and bending cycle timer for program monitoring.

- I/O view/check of components and functions

- Self-diagnostic program

- Mandrel auto lubrication function

- Mandrel anticipated extraction for working with ball mandrel.

- Network connection ready to YLM server for trouble shooting

Hardware:

- PC-Based Industrial computer

- 15″ LCD colour touch screen monitor

- Solid State hard disk

- USB port

- Ethernet card

- 2 Parallel Part / 1 Serial Port

Technical Description:

- Max OD Mild Steel: 80 mm

- Max WT: 3 mm

- Max bending angle: 190 degrees.

- Max mandrel working distance: 3000 mm Slave feed / 4000mm hitch feed.

- Feeding speed: 900 mm/sec

- Rotating speed: 270 degree/sec

- Bending speed: 90 degree/sec

- Feeding accuracy: 0.1 mm

- Rotating accuracy: 0.1 degree

- Bending accuracy: 0.1 degree

- Hydraulic Pump: 34.5 Kw

- Total motor power: 36.55 Kw

- Max hydraulic pressure: 140 kg/cm ²

- Oil tank capacity: 420 litres

Machine dimension:

- Length: 6500 mm

- Width: 2500 mm

- Height: 188 mm

- Weight: 6000 kg

- Working Height: 1170 mm

Standard Accessories:

- Bending tooling 1 set

- Mandrel rod 3 pc

- Wiper die holder: 1 pc

- Safety plate with bending arm 1 pc

- Tool box 1 pc

- Manual 1 pc

- Wiring Drawings 1 pc

- Hydraulic Drawings 1 pc

- Pneumatic Drawings 1 pc

Spare parts with machine shipment:

- Proximity switch 1 pcs

- Fuse (5A) 10 pcs

- Oil seals + O ring 1 set

- IO Card 1 pc

- System recovery CD 1 pc

- Hard disk 1 pc

Options:

- Internal Collet

- Extra Tooling Sets

- Bed Extension Per metre

- Last Bend Tube Boosting Function

- Electric Follower Slide

- Electric Mandrel Extraction

- Fully Enclosed CE Guarding

- Tube Cropping Unit

- Auto Loading System

- Fully Automatic Machine Lubrication

- Separate Laptop Computer with YLM CNC software installed for off-line programming.