IMET – KS 502 – Semiautomatic Bandsaw

Specifications

| Make | IMET |

|---|---|

| Model | KS 502 |

Description

IMET – KS 502 Semiautomatic Bandsaw

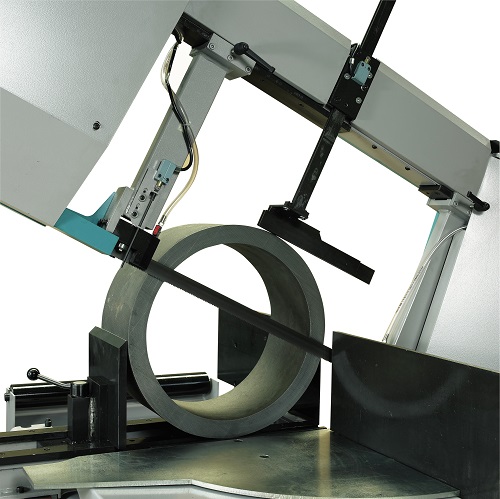

Double column semiautomatic bandsaw

KS 502 can cut right and left up to a 60°.

Cutting capacity at 90°, Round: 350mm

Vice – The vice slides transversally on the work surface, linear guides, locking and rapid approach, complete with standard pressure reducer. All the saws of KS series (450, 502, 620 and 652) allow to fix the material clamping vice only once and then to rotate the arc for cutting both right and left (up to 60 °).

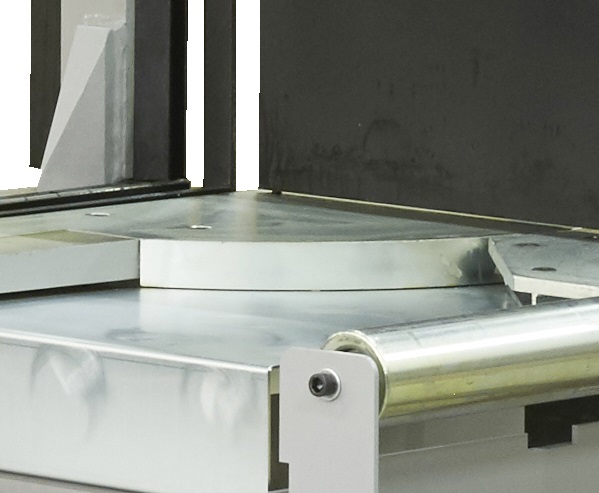

Working table – Easy to use thanks to the rotating work surface integral with the arc and the blade passage to optimize the material support system during processing in all angles.

Angle cutting precision – The cutting precision is ensured by the graduated scale (on the work surface) which constitutes a visual reference for the operator in case of angle cutting. There’re also automatic stops at 45°left, 0 ° and 45 ° right. To increase cutting precision, IMET band saws are equipped of a system for detecting degrees of cut away from the center.

Sawframe – In electro-welded steel, the blade has an inclination of 6 ° to improve the penetration in the material and optimize the execution of the cut. The rotation of the arc is done by bearing preloaded. The blade of KS 502 has a tensioning of 2000kg / cm2 and is equipped with a control microswitch for immediate stop in case of blade breaking or power failure.

Blade guides – Easily adjustable thanks to their positioning on special linear guides, the blade guides of KS 502 have carbide inserts and additional bearings for better blade alignment.

Material detection device – To facilitate the approach of the blade to the material KS502 mounts a device for detection of automatic cutting start and end point.

Control console – External to the machine and mobile, the control console allows you to manage all KS 502 operations and is equipped with LED for checking the blade tension with the possibility of controlling the descent speed of the bow and the force of penetration into the material. The operator can choose from several options for the purpose cut: ascent of the bow with stopped blade, ascent of the bow with a moving blade, end of cycle without bow ascent.

Technical Information

| Cutting capacity at 90° | Round: 350mm Square: 330mm Rectangular: 500x310mm |

| Cutting capacity at 45° left | Round: 300mm Square: 300mm Rectangular: 300x320mm |

| Cutting capacity at 45° right | Round: 320mm Square: 320mm Rectangular: 320x320mm |

| Cutting capacity at 60° left | Round: 150mm Square: 150mm Rectangular: 150x320mm |

| Cutting capacity at 60° right | Round: 150mm Square: 150mm Rectangular: 150x330mm |

| Cutting capacity (BUNDLE) | Max: 500x250mm Min: 160x40mm |

| Cutting capacity at 90° for solids(C45) | 280mm |

| Min. scrap-end with bundle | 235mm |

| Blade motor | 2.2KW |

| Blade speed | Da 15 a 100 m/min |

| Blade size | 4250x34x1.1mm |

| Blade tension | 2000kg/cm2 |

| Weight | 1200kg |

You may also like…

-

Sale!

![MACKMA – BM60 – Rotary Draw Bending Machine [NOW $22,000+GST] In-Stock List](data:image/svg+xml;base64,PHN2ZyB4bWxucz0iaHR0cDovL3d3dy53My5vcmcvMjAwMC9zdmciIHdpZHRoPSIzMDAiIGhlaWdodD0iMzAwIiB2aWV3Qm94PSIwIDAgMzAwIDMwMCI+PHJlY3Qgd2lkdGg9IjEwMCUiIGhlaWdodD0iMTAwJSIgc3R5bGU9ImZpbGw6I2NmZDRkYjtmaWxsLW9wYWNpdHk6IDAuMTsiLz48L3N2Zz4=)

MACKMA – BM60 – Rotary Draw Bending Machine [NOW $22,000+GST]

Original price was: $26,000.00.$22,000.00Current price is: $22,000.00. -

IMET – KTECH 502 F2000 – Automatic Double Column Bandsaws

-

In-Stock List

-

Sale!

![MACKMA – BM48 – Rotary Draw Bending Machine [NOW $19,500+GST] MACKMA - BM48 - Rotary Draw Bending Machine [NOW $19,500+GST]](data:image/svg+xml;base64,PHN2ZyB4bWxucz0iaHR0cDovL3d3dy53My5vcmcvMjAwMC9zdmciIHdpZHRoPSIzMDAiIGhlaWdodD0iMzAwIiB2aWV3Qm94PSIwIDAgMzAwIDMwMCI+PHJlY3Qgd2lkdGg9IjEwMCUiIGhlaWdodD0iMTAwJSIgc3R5bGU9ImZpbGw6I2NmZDRkYjtmaWxsLW9wYWNpdHk6IDAuMTsiLz48L3N2Zz4=)

MACKMA – BM48 – Rotary Draw Bending Machine [NOW $19,500+GST]

Original price was: $22,000.00.$19,500.00Current price is: $19,500.00.

![MACKMA – BM60 – Rotary Draw Bending Machine [NOW $22,000+GST] In-Stock List](https://www.delahenty.com.au/newwp/wp-content/uploads/2021/08/2024-11-Mackma-BM60-300x300.jpg)

![MACKMA – BM48 – Rotary Draw Bending Machine [NOW $19,500+GST] MACKMA - BM48 - Rotary Draw Bending Machine [NOW $19,500+GST]](https://www.delahenty.com.au/newwp/wp-content/uploads/2021/07/5875294.o-300x300.jpg)