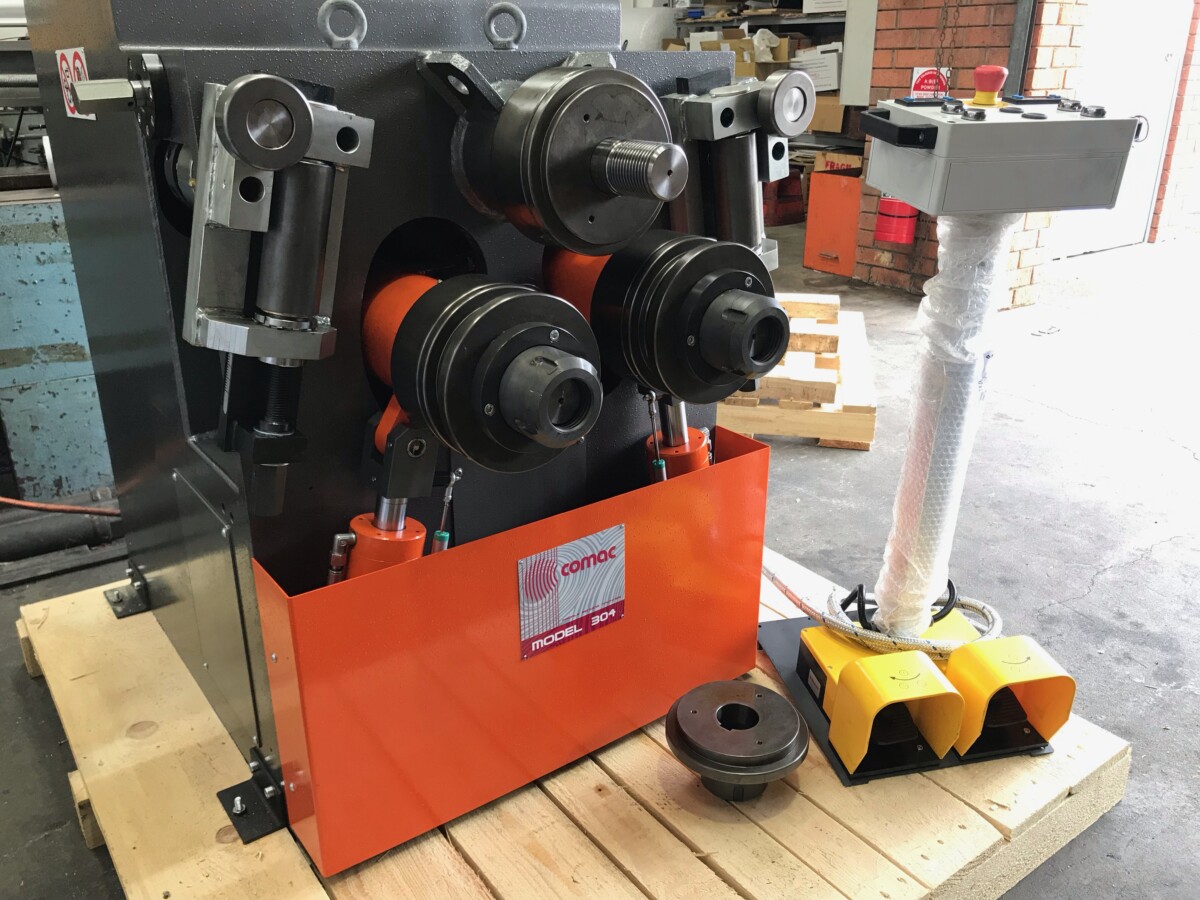

COMAC – SERIE 3000 – MODEL 304HV – Section and Profile Rolling Machine

Specifications

| Make | COMAC |

|---|---|

| Model | 304HV |

| Series | 3000 |

Description

COMAC – SERIE 3000 – MODEL 304HV – Section and Profile Rolling Machine

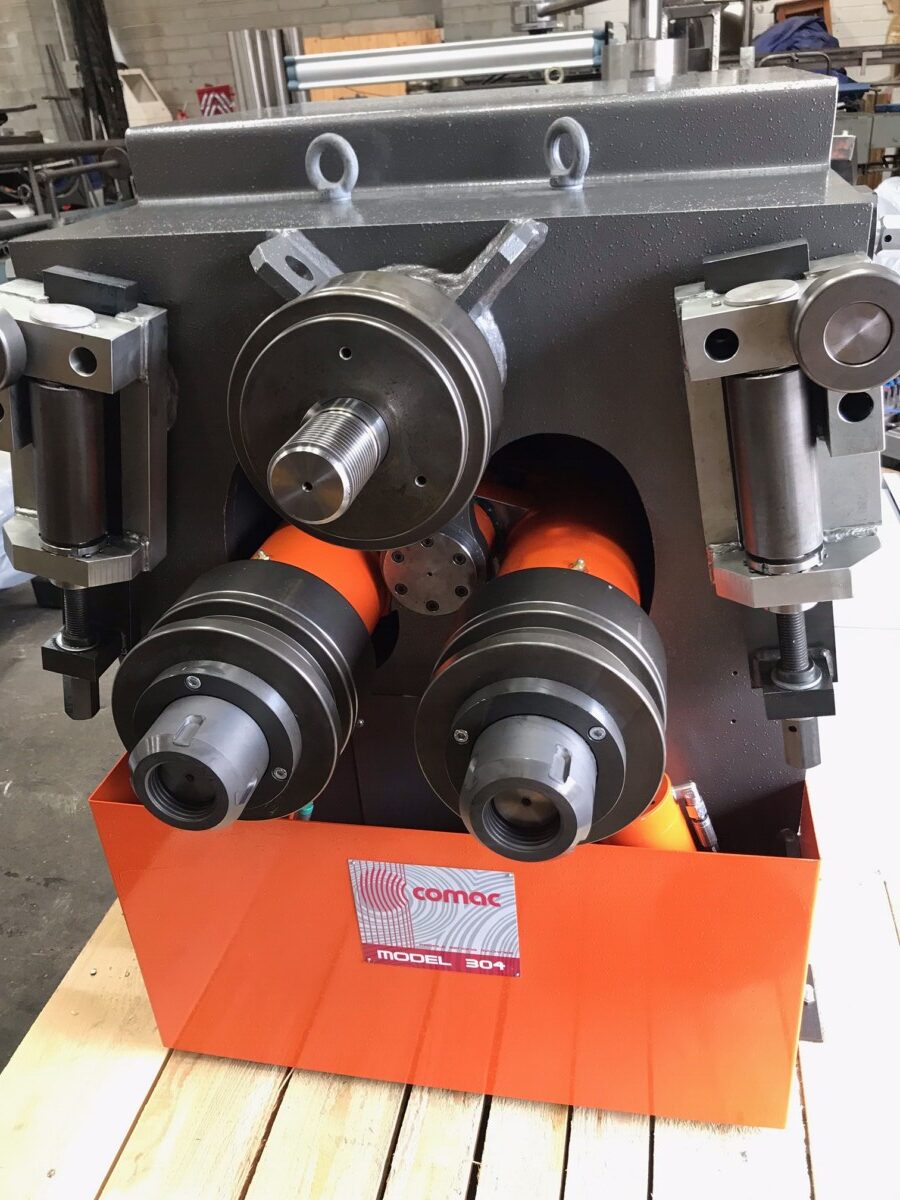

- 3 driving rolls to guarantee maximum drive on the profile

- Bending rolls independently adjustable, for double pre-bending capability

- Fully adjustable lateral guide rolls

- Machine supplied with universal rolls for Flat, angle and solid bars

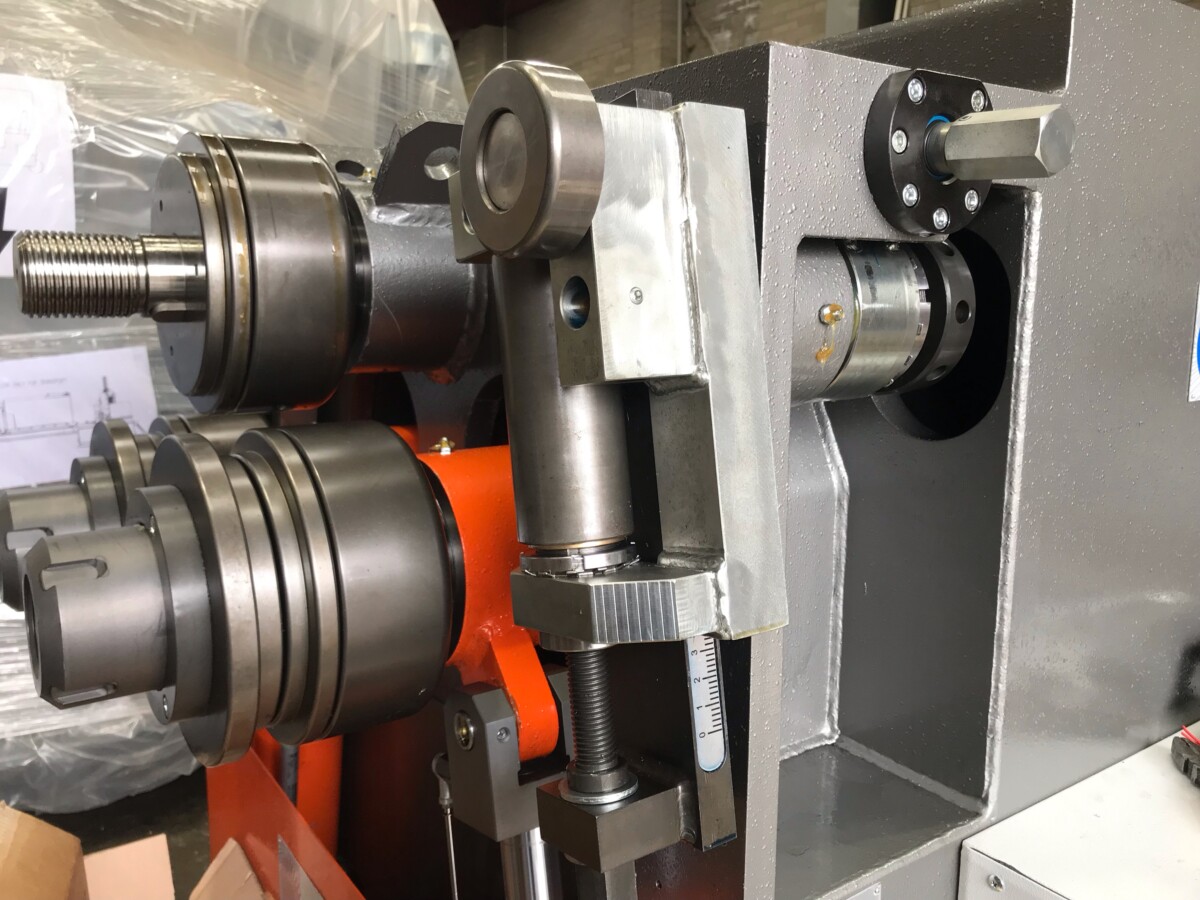

- Digital read out for position of bending rolls

- Free-standing remote-control pedestal

- Possibility to operate machine both in vertical and horizontal position

- One-piece fabricated steel frame

- Torque limiter installed on top roll shaft

- Shaft and pinions installed on high dynamic load roller bearings

- Gears coupled on splined shafts

CNC model also available

- Section modulus [cm³] 10

- Diameter of shafts (Upper/Lower) [mm] 60

- Diameter of rolls [mm] 205

- Power output [kW] 3,5

- Rolling speed [m/min] 5,2

- Weight [kg] 1090

Control Options

- Standard machines are controlled using a push-button board that allows the variation of the position of the bending rolls and by a pedal that controls the advance and retreat of the profile.

- Depending on the deformation work to be performed, numerous additional controls are available, for example, the hydraulic regulation of the lateral guide rolls, the speed regulation using a potentiometer, the double speed positioning of the bending rolls, and the remote control of the special tooling.

- In case high repeatability is required or particular bending geometries must be achieved, the machines are equipped with a programmable positioner (NC), numerical controls with independent axes, and numerical controls with interpolated axes (CNC).

Read about other companies that have bought COMAC Section Rollers.