The dawn of a new era is upon us, one in which manufacturers can unlock the potential of collaborative robots (cobots) and reap their many benefits. As technology advances and becomes more accessible, we have seen an increase in the use of these cobots across multiple industries. Cobots can be used for various tasks such as assembly line production, quality control, material handling, and much more. This article will explore how utilising cobots can streamline processes for manufacturers while increasing efficiency and safety on the job site.

Automation Flexibility

Manufacturers have always sought to automate their production processes in order to reduce costs and improve efficiency. As robotic technology has advanced, so too have the opportunities for manufacturers to leverage automation’s flexibility. Cobots are a prime example of this—a type of robot designed specifically with automation-friendly features that can be quickly reprogrammed or reconfigured according to changing requirements. These robots are also autonomous, meaning they don’t need continuous human supervision during operation.

Furthermore, since most cobots can be equipped with sophisticated sensors and vision systems, they can autonomously detect objects on the production line and adjust accordingly. This makes them ideal for applications where product batches vary significantly or require frequent changes due to new customer demands.

The cost-efficiency of cobots makes them a desirable asset for many manufacturers. The upfront costs associated with cobots can be lower than those of traditional robot automation since they typically require less additional components and infrastructure such as safety fencing or caging. This means fewer expenses in terms of setup, installation, and maintenance over time.

Cobots are designed to work collaboratively with humans, they do not need their own dedicated workspace nor an expensive guarding system like other industrial robots may require; this further reduces the financial burden on companies who use them.

In addition to initial setup costs being reduced by using cobots, there is also potential for long-term money savings when compared to more traditional robotic solutions. Cobots can perform multiple tasks simultaneously and efficiently – something that could prove invaluable in streamlining operations within a manufacturing environment. Additionally, thanks to their flexibility, cobot models can easily be repurposed from one task to another without having to purchase new hardware or software which again helps keep operational costs low. In short, investing in cobots is an effective way for manufacturers to achieve increased cost-effectiveness while still maintaining efficiency levels at the same time.

By incorporating artificial intelligence and machine learning in cobot technology, companies can reduce costs associated with hiring human labour by automating dangerous or tedious manual tasks.

Safety

Cobots offer enhanced workplace safety as they are designed to work collaboratively alongside humans without any risk of injury or harm. By having them carry out hazardous jobs like welding or operating dangerous machinery, workers no longer need to put themselves at risk every day just to do their job.

Cobots are designed to be used safely in close proximity to people without the need for physical barriers or extensive safety training. In addition to providing greater agility than traditional robots, cobots also boast increased safety measures like built-in power cut offs and light curtains that protect humans working nearby. One key feature that robotic devices have is an emergency stop (e-stop) function which enables operators to quickly stop the current program running without risking injury or damage in case something unexpected happens.

By allowing operators and engineers alike to interact closely with machines without fear of injury, cobots make it easier for manufacturers to reap all the benefits of automated production while ensuring a safe environment for their workforce.

Adaptability In The Workplace

Cobots offer manufacturers great adaptability in the workplace. Cobot technology allows for changes in production quickly and easily, giving a manufacturer the ability to produce different products flexibly and efficiently. With cobots, manufacturers can adjust the size of their workforce according to customer orders or changing market conditions, allowing them to remain competitive.

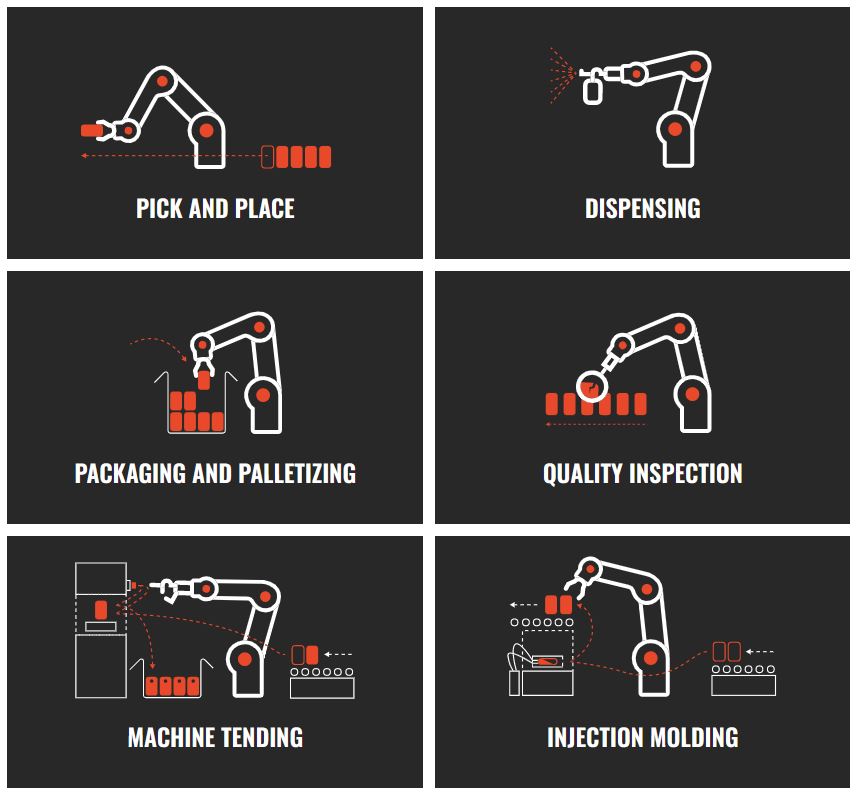

Cobots can be employed in a wide range of applications depending on the end-effector attached to them and this allows them to carry out tasks such as pick-and-place, dispensing, welding, injection moulding, packaging, and palletizing, quality inspection, sanding and polishing, machine tending only to mention a few.

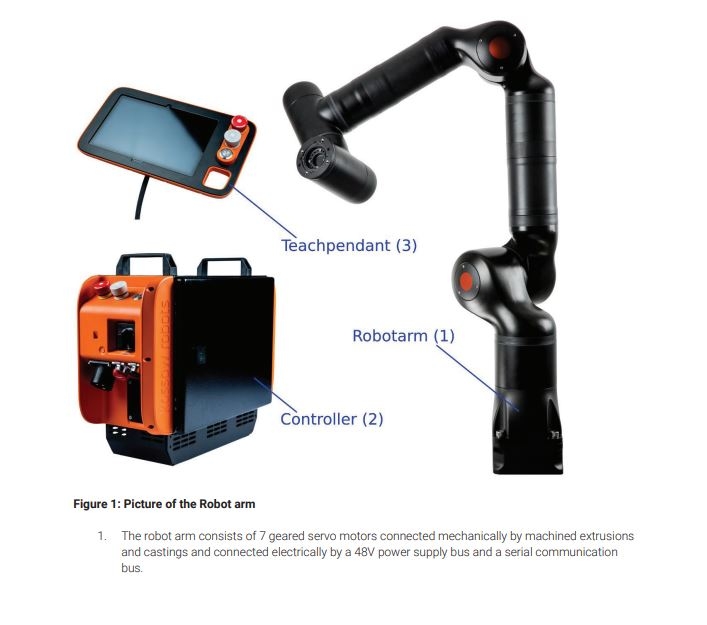

The most commonly used type of cobot is the articulated robot arm which features multiple joints that allow it to have both translational and rotational motion freely in the X, Y, and Z axes. These robots have excellent dexterity and accuracy, allowing them to carry out highly precise movements with ease. A good example is the 7-axis arm made by Kassow robot which is both flexible and efficient.

The benefits don’t stop there: cobots also allow for an easier transition from one product line to another without any major retooling required. The versatility of cobots makes them ideal for use in new and expanding industries such as 3D printing, robotics assembly lines and medical device production. Furthermore, since most cobots come pre-programmed with basic tasks already in their system, they require minimal training before beginning operation; this reduces both startup time and labour costs associated with getting up and running quickly. For these reasons, many manufacturers consider implementing cobots in their operations to increase productivity while decreasing overhead expenses related to personnel and retooling requirements.

With their wide range of capabilities combined with user-friendly programming interfaces, cobots are revolutionising many aspects of modern manufacturing by enabling operators to do more with less time and effort.

Time Savings

Despite the potential cost-effectiveness of cobots, some manufacturers may be reluctant to invest in them for fear that they will not reduce production time or labour costs. However, this could not be further from the truth; as cobots are able to automate more complex tasks than traditional robots and help improve overall efficiency within manufacturing processes, it is very possible to realise tangible time savings over the longer term.

The implementation of cobots has been proven to provide a wide range of automation benefits for businesses – including increased productivity due to their ability to take on high-volume, repetitive tasks which would otherwise require manual input.

Cobots can also work alongside human employees or independently depending on specific application; and this flexibility means that businesses can scale up operations quickly and easily when needed, without having to worry about recruiting new staff or training existing personnel. This ensures that all jobs get completed efficiently while limiting any disruption caused by unpredictable changes in workloads or customer orders. Ultimately, cobots offer an efficient automated solution that helps increase profits while reducing unnecessary expenses – making them an invaluable asset for manufacturers looking for long-term success through improved efficiency.

Increased Productivity

The introduction of cobots to manufacturers has enabled increased productivity in production. By integrating cobot technology into existing operations, companies can increase their overall productivity without investing heavily in automation infrastructure.

Manufacturing productivity is improved when using cobots as they can perform repetitive tasks quickly and accurately with minimal human intervention. Automation productivity is also enhanced due to the cost savings associated with using a cobot instead of hiring additional staff members or purchasing more expensive automated equipment. Additionally, flexible productivity gains can be achieved by programming the cobots for different applications over time, which reduces the need for costly retraining programs. Furthermore, having a cobot on site allows employees to focus their attention more efficiently on higher-value tasks such as problem solving and creative thinking. This leads to an increase in customer satisfaction levels since products are produced faster and better than before.

Cobots offer numerous advantages for manufacturers looking to boost their operational efficiency while improving output quality at the same time. The ability of these robots to integrate easily into existing production lines makes them attractive from both economic and practical standpoints. As well as reducing labor costs, they provide greater flexibility compared to traditional automation solutions while ensuring optimal safety levels within the workspace environment.

Greater Precision

These cobots also allow for greater precision when it comes to complex operations due to their ability to make accurate calculations quickly. They provide improved accuracy in data collection compared to traditional methods while eliminating potential errors caused by humans.

With improved accuracy and consistency compared to manual workers, there is less wastage in terms of materials and resources during the production process. As such, many manufacturers have seen reductions in both labour costs and total operational times by investing in cobot technology.

Connectivity To Other Machines And Systems

Cobots are designed to be highly compatible with other machines and systems. Equipped with numerous communication protocols such as Modbus TCP or RTU, Ethernet, RS485 and Profinet(only to mention a few), this enables them to interact seamlessly with the existing production infrastructure, thus resulting in increased productivity and efficiency within a manufacturing process. Cobot’s machine-connectivity feature allows for system integration, interoperability, data exchange, and robot networking. All of these capabilities aid manufacturers by providing access to real-time data from multiple sources that can then be used to optimize workflow processes or make changes on the fly if needed.

The ability for cobots to communicate effectively and easily with other machines also makes it easier for human operators to monitor their performance without being physically present. This can help reduce labor costs associated with manual monitoring as well as increase safety by eliminating physical contact between humans and potentially hazardous machinery operation. Finally, this increased robotic connectivity is helping many manufacturers become more agile while reducing operational costs at the same time.

Environmental Impact

Moreover, compared to older models of machines used in manufacturing processes, cobots do not produce as much noise pollution or vibration due to their lightweight design and smoother movements. This ensures fewer disruptions both inside and outside of factories where workers’ health could be at risk from excessive noise exposure or vibrations from heavy machinery operation. In addition, many modern cobot designs use non-toxic materials making them safer for human contact and even include sensors that alert operators when there is a potential hazard nearby such as heat or radiation sources. Ultimately this provides greater protection for employees working alongside these robots leading towards healthier work environments.

Conclusion

Overall, the use of cobots is proving beneficial for many manufacturers worldwide by providing reliable automation solutions that save time and money while enhancing workflow efficiencies throughout the industry.

Cobots automation-friendly features allow for quick reprogramming or reconfiguration allowing businesses to adapt to changing business requirements. By leveraging the power of this technology, businesses can not only improve output and safety but also gain access to innovative tools which could revolutionise how they approach manufacturing processes in the future.

In short, cobot technology offers numerous advantages that should make it highly desirable for any manufacturer looking to improve its bottom line while minimising its environmental footprint.