In the world of advanced manufacturing, precision and efficiency are paramount. YLM Hannsa, a division of Ying Han Technology Co., Ltd., has carved a niche for itself by delivering high-performance CNC lathe solutions that meet the rigorous demands of modern machining. With over 30 years of experience, the company has become a trusted name globally, offering a diverse range of CNC equipment tailored for industries ranging from automotive to aerospace.

YLM Hannsa’s CNC lathe lineup is engineered to deliver exceptional accuracy, speed, and durability. Two standout series define their lathe offerings:

Box Way Series

- Heavy-Duty Construction: Designed for robust cutting tasks, the Box Way Series features hardened slideways that provide superior rigidity and vibration damping.

- High Torque Spindle: Ideal for heavy material removal, this series excels in demanding environments.

- Precision Engineering: The machine structure ensures minimal deformation, maintaining accuracy over long production runs.

![HANNSA - Heavy Duty CNC Lathe [Box Ways on 2 Axes - YTH 10E] HANNSA - Heavy Duty CNC Lathe [Box Ways on 2 Axes - YTH 10E]](https://www.delahenty.com.au/newwp/wp-content/uploads/2021/07/hannsa-yth-10e-cnc-lathes-1024x1024.jpg)

Linear Way Series

- Smooth Motion & Accuracy: Incorporates linear guideways for reduced friction and enhanced precision.

- High-Speed Machining: Equipped with fast spindles and advanced CNC controls for efficient cycle times.

- User-Friendly Interface: Simplifies complex programming tasks, making it accessible for operators of all skill levels.

- Economically Priced: With a high level of performance.

![HANNSA - CNC Lathe [Linear Way Series - YTL 8540 / 8540M] HANNSA - CNC Lathe [Linear Way Series - YTL 8540 / 8540M]](https://www.delahenty.com.au/newwp/wp-content/uploads/2021/08/hannsa-ylt-8540-cnc-lathe-linear-way-series.jpg)

Key Features Across the YLM Hannsa CNC Lathe Range

30° / 45° Slant Saddle Design: Enhances chip flow and operator ergonomics.

Automatic Tool Changer: Minimizes downtime and boosts throughput.

High-Precision Ball Screws: Ensures tight tolerances and consistent part quality.

Efficient Chip Removal System: Maintains a clean workspace and prevents machining disruptions.

Hydraulic 3-jaw Chuck: Each machine comes with a hydraulic 3-jaw chuck as standard equipment.

![HANNSA - Heavy Duty CNC Lathe [Box Ways On 2 Axes - YTH] HANNSA - Heavy Duty CNC Lathe [Box Ways On 2 Axes - YTH]](https://www.delahenty.com.au/newwp/wp-content/uploads/2021/08/YTH-twin-1024x890.jpg)

Optional Features

These Heavy Duty CNC Lathe and Box Ways machines offer a wide array of optional enhancements designed to boost versatility and performance:

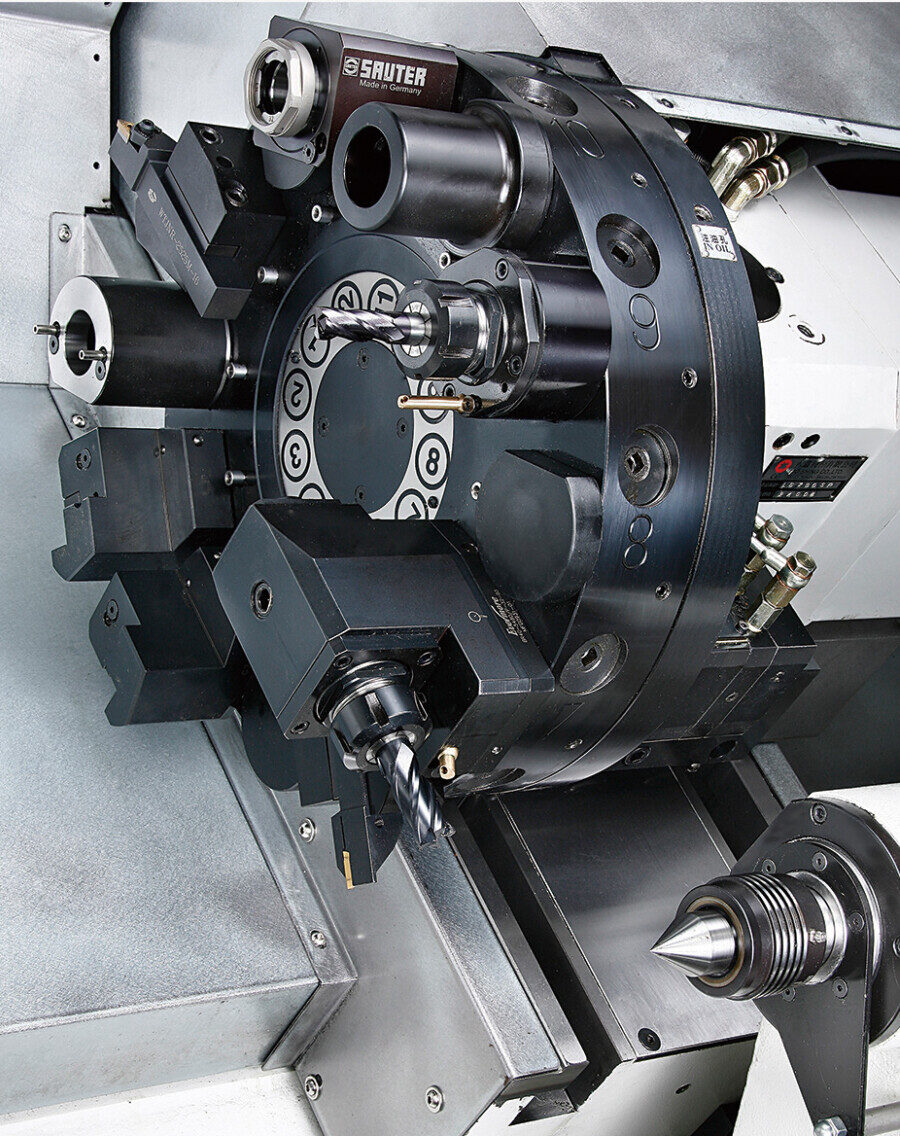

Power Turret

- Works in conjunction with the spindle’s C-axis to enable milling, drilling, and tapping operations.

- Equipped with a dedicated servo motor for turret rotation and indexing, ensuring rapid tool changes and precise positioning.

- The tool holder interface allows for quick and efficient tool swaps.

- Delivers repeatability accuracy of up to 0.003 mm.

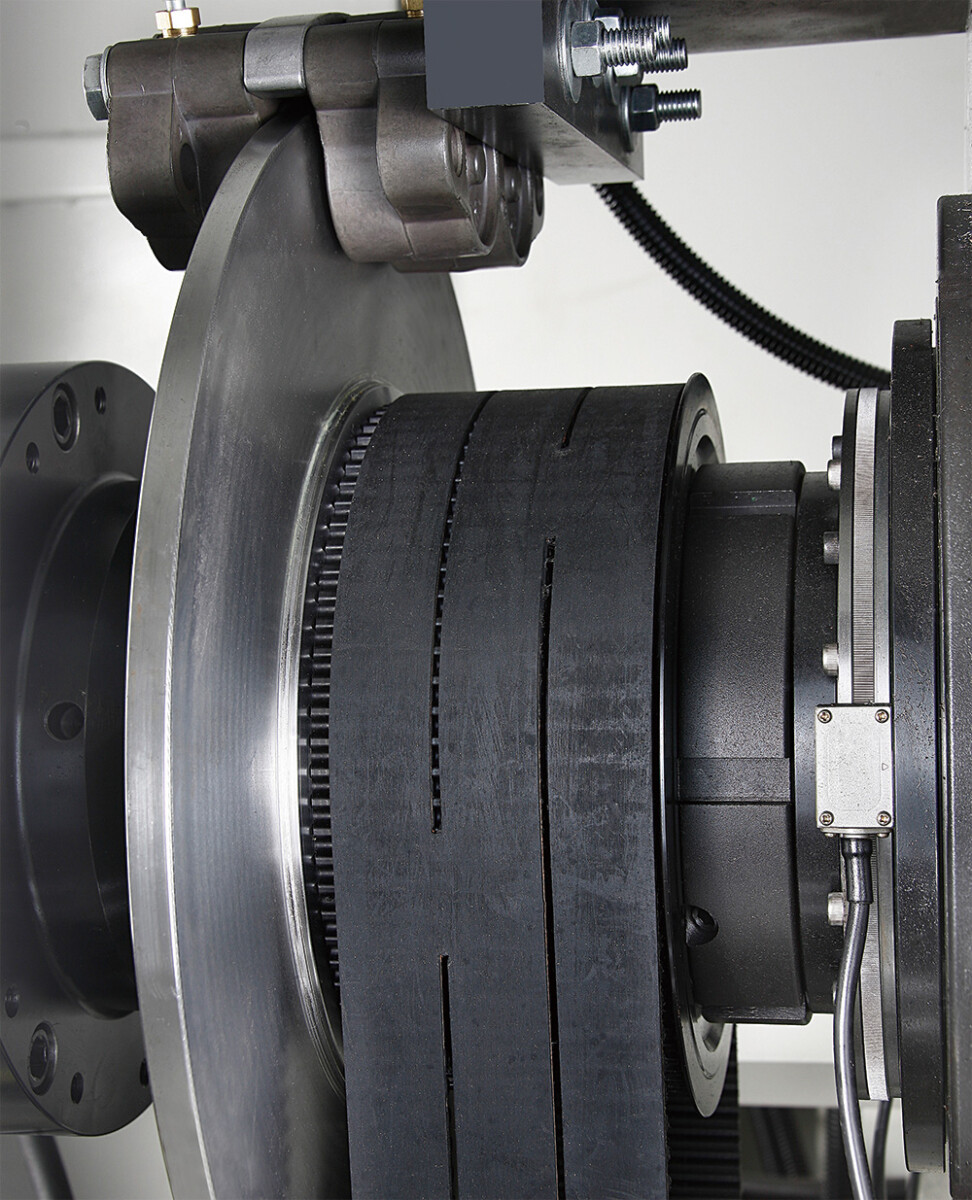

High-Quality Coupling

- The X and Z axes are directly driven by servo motors via premium couplings.

- This setup guarantees smooth and precise movement along both X and Y axes.

C-Axis Function

- Enables contour machining through spindle rotation control.

- Ideal for milling, drilling, and tapping tasks, enhancing machining flexibility and productivity.

- Offers indexing accuracy of 20 arc seconds.

Quill Travel Detection

- The tailstock features a sensor that monitors quill position.

- If displacement is detected, an alarm is triggered and the machine halts automatically to ensure operator safety.

Parts Catcher

- Facilitates easy and efficient collection of finished parts after machining.

Tool Setter

- Utilises a touch sensor to accurately measure tool length.

- Minimises the need for repeated cutting tests, saving time and improving setup efficiency.

Bar Feeder

- The optional bar feeder enhances automation, enabling continuous and efficient machining operations.

- Available in multiple specifications to accommodate a wide range of bar sizes, tailored to meet individual customer requirements.

The YLM Hannsa team continuously integrates feedback from international clients to refine its designs and stay ahead of industry trends.

Conclusion

Whether you’re a small shop looking to upgrade your capabilities or a large-scale manufacturer seeking reliable, high-performance equipment, YLM Hannsa CNC lathes offer a compelling blend of innovation, durability, and precision. Their commitment to quality and customer satisfaction makes them a formidable player in the CNC machining landscape.

About Delahenty Machinery

We are a prominent importer and supplier of machinery solutions for the metal forming, manipulation, and cutting industries. We offer a wide range of top quality machines from some of the top international manufacturers.

Contact us today and experience the best service in the industry.