RICO – Guillotine Shears – HGR Range

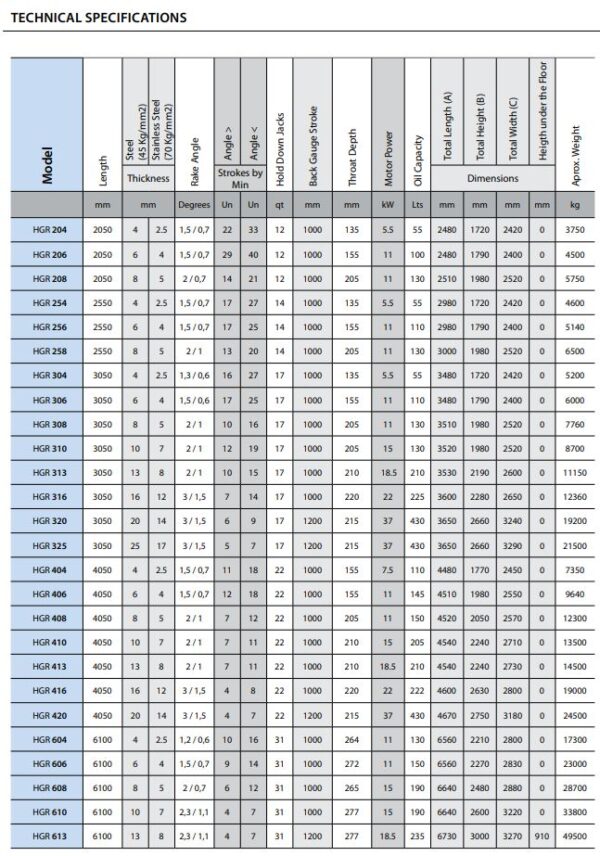

Specifications

| Make | RICO |

|---|---|

| Model | Guillotine Shears |

Description

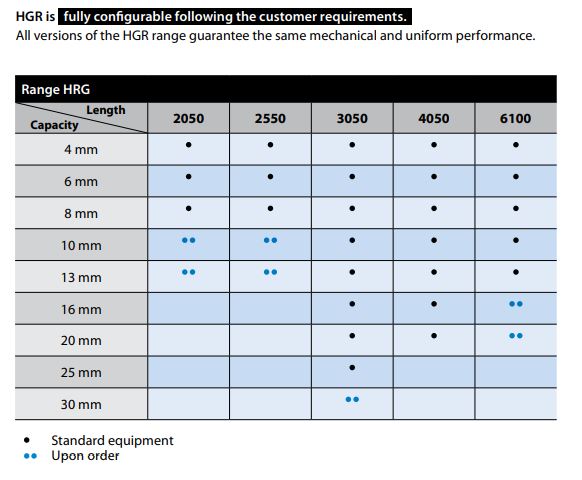

Guillotine Shears – HGR Range

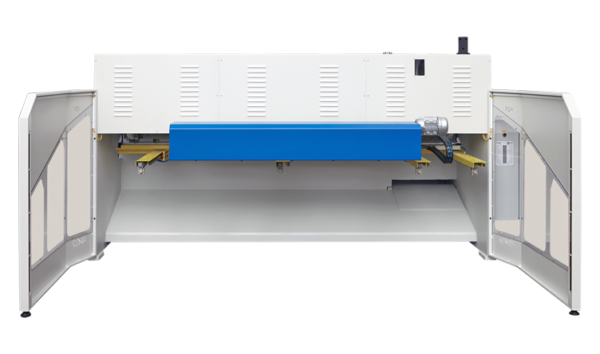

Rico HGR guillotine shears are a certainty of dimensionally accurate cuts with no burr, no helix, no bow and no twisting in any thickness and in any type of plate. The design principle is based on the vertical cutting principle with angle variation and a robust structure in which the blade beam is supported on adjustable bearings along its entire length.

This technology, developed over decades of experience, allows you to adjust the best suited cutting angle according to the characteristics of the plate and therefore the cut is smooth and balanced throughout its length.

Features:

- Vertical cut

- Variavel rake angle

- Blades holder supported by adjustable bearings

- Elgo P40 control

- Management of energy saving Standby Function

- Strong back gauge equipped with high quality hardened ball screws

- RAE system (RICO)

Customer Benefits:

- Reliability:

All structural parts are calculated by the finite element method and only high quality steel S275 and S355 JR namely J2 (+ N) is used. - Vertical cut and variable rake angle

The Rico shears are machines of vertical cut (the blades beam is supported by bearings) allowing different angle depending on the thickness of the sheet material , situation that can’t be possible in swing beam cutting shears, where the angle is steady. - Structure

The structure of HGR is designed to ensure the best balance and less deformation during cutting. It is a single unit welded construction and reinforced sheet-quality and certified, properly dimensioned. - Operation

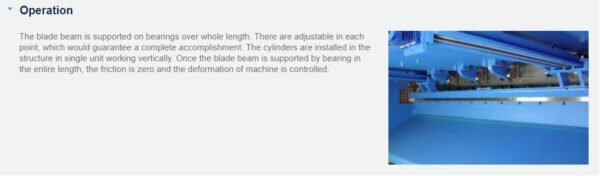

The blade beam is supported on bearings over whole length. There are adjustable in each point, which would guarantee a complete accomplishment. The cylinders are installed in the structure in single unit working vertically. Once the blade beam is supported by bearing in the entire length, the friction is zero and the deformation of machine is controlled.

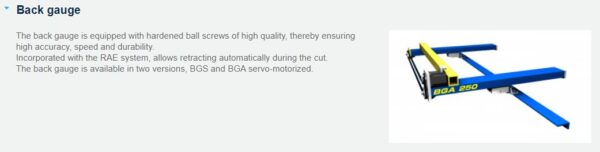

Back gauge

The back gauge is equipped with hardened ball screws of high quality, thereby ensuring high accuracy, speed and durability.

Incorporated with the RAE system, allows retracting automatically during the cut.

The back gauge is available in two versions, BGS and BGA servo-motorized.