NINGBO – Electro Permanent Magnetic Chuck (EP75 Series)

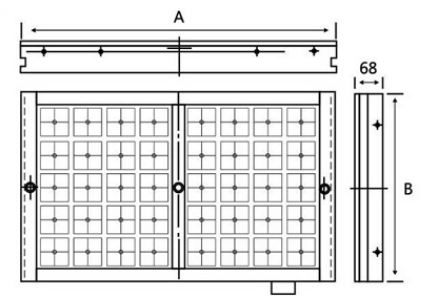

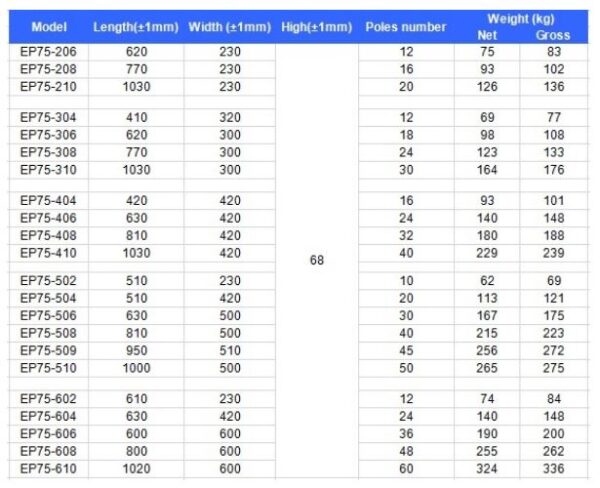

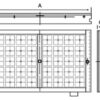

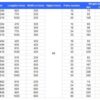

Specifications

| Make | NINGBO |

|---|---|

| Series | EP75 |

Description

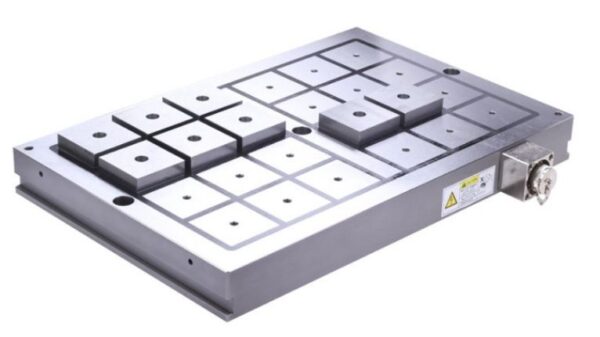

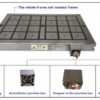

NINGBO – Electro permanent magnetic chuck (EP75 Series)

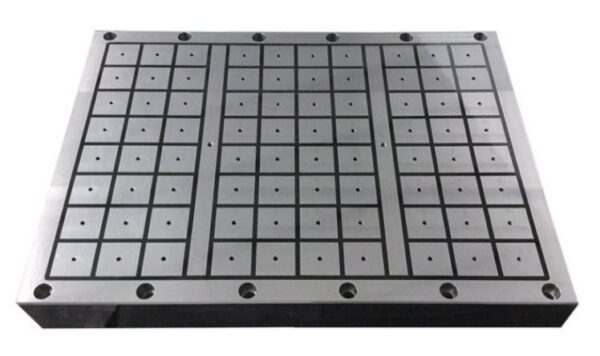

- Comprising 75mm*75mm poles with a force of 15-17kgf/ cm2.

- It is possible to predetermine the force generated by counting the number of poles, work piece gripping at least 4 pole contact faces.

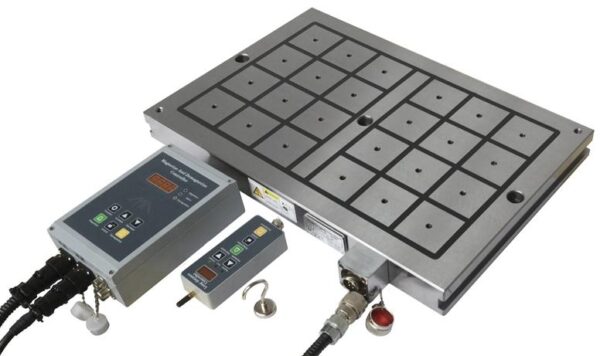

- Controller do the Magnetizing or demagnetizing in 0.5~5 seconds.

- Chuck is tested for Slippering force, Waterproof test, Temperature rise test, Electrical & Demagnetizing tests

USE

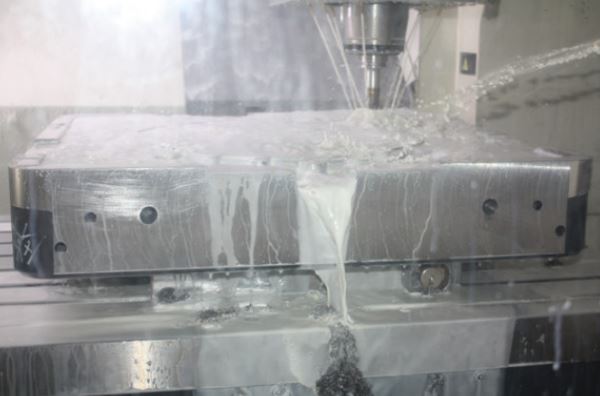

- Used for normal and heavy duty drilling, milling, and CNC machining center

- Best used for the workpieces at least 400*400 mm and 18 mm thick. Ideal for general pieces of various dimensions with normal operating air gaps and medium thicknesses

Standard Features and Benefits

- Flexibility

Allow single set-up machining with 5-sided accessibility

Workpieces larger than the table are machinable - Safety

No electric power supply during clamping

Constant and uniform magnetic power over entire area.

No temperature rise in operation. so no impact on precision and work piece deformation due to temperature rise. Can used for long time. - Efficient

Easy and quick position, reduce set-up time and increase available machine time.

High accuracies and tolerances - Cost-effectiveness

No maintenance

No machine modifications

Reduced tool consumption

Range of products include

- Electro-permanent magnetic chuck

- Permanent magnetic chuck

- Permanent magnetic lifter

- NbFeB magnets and other related products

Those products are widely used for CNC machine, milling, grinding turning, molding applications and other industry field etc.

![FONG HO – FHC-350P – Circular Cold Saw [Pneumatic] FONG HO - FHC-350P - Circular Cold Saw [Pneumatic]](https://www.delahenty.com.au/newwp/wp-content/uploads/2021/07/fong-ho-fhc-350p-circular-cold-saw-300x300.jpg)