MACKMA BTT75 Chip Briquetter

Specifications

| Make | MACKMA |

|---|---|

| Model | BTT75 |

Description

MACKMA BTT75 Chip Briquetter

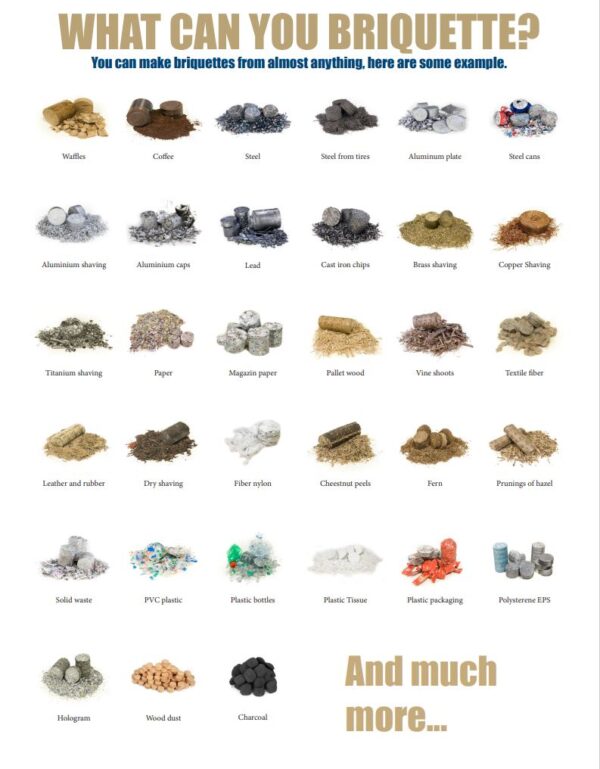

The Mackma briquetting machine range, versatile and compact solution, compresses metal shavings and recovers processing oil or emulsified coolant.

Able to briquette iron, aluminum, steel, stainless steel, cast iron, copper, brass, bronze and even some types of plastic. The machine works automatically, can be timed and can be interfaced with lathes or machine centers.

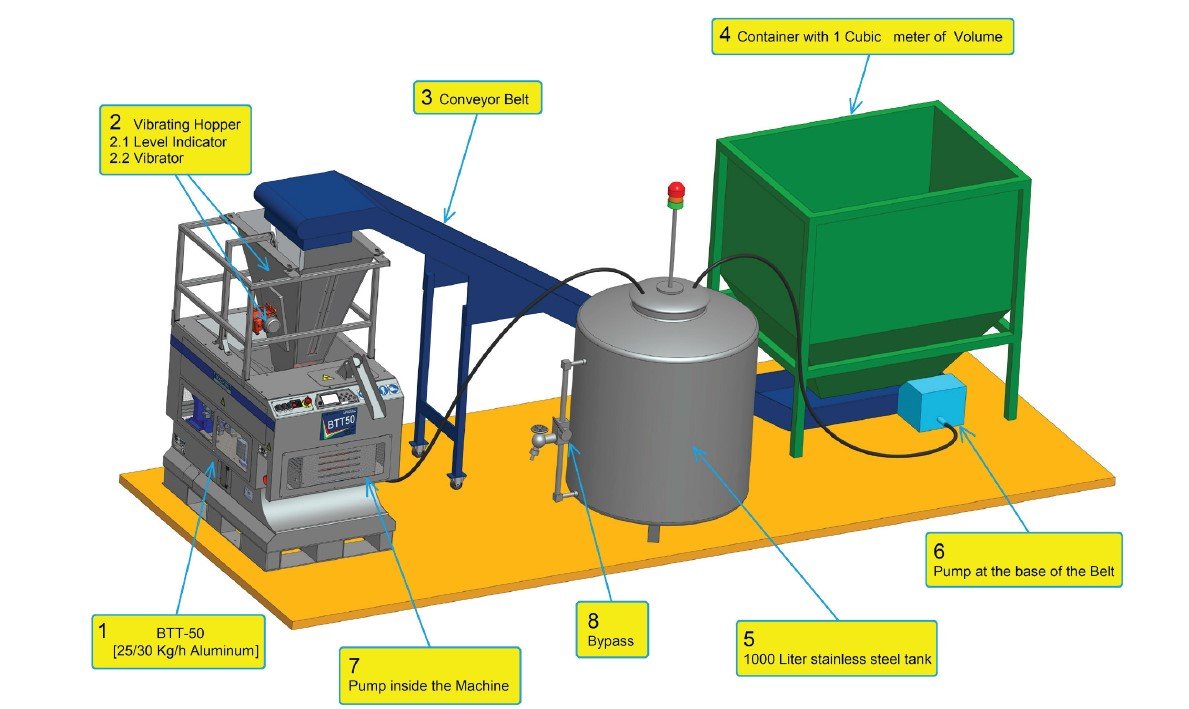

It has various accessories such as an external shredder to reduce the size of long chips or skeins; an external hopper with vibrator for shavings that tend to compact; an integrated drainage system for chips with a high percentage of oil; an ultrasonic level sensor to check the filling status of the hopper.

The main advantages of using our briquetting machine are:

- Volume reduction -90%

- Reduction of handling and transport costs -80%

- Reduction of recycling costs

- Reduction of environmental impact

- Reduction of environmental pollution

- Increase in value and melt yield + 90%

- Oil recovery

- Compact footprint allows for placement at the work center

Technical specifications BTT75

- Briquette diameter 75 – mm

- Production rate (Kg/hour) Aluminum 90÷100

- Production rate (Kg/hour) Iron 180÷200

- Machine used for the compression of metallic chip removed through metalworking operations

- Several benefits, such as: – Machining operation with automatic cycle (no manpower for chip handling) – Recovery of plant areas – Re-use of recovered oil by briquette machine

- Easy to use

- Reduced dimensions Suitable for all plant layouts

- Chip material to be compressed: all materials with mechanical machining residues (iron, aluminum, brass, saw, others)

- Application fields: All sectors with mechanical machining