HANNSA – YBH 3000A & 3000B – CNC Horizontal Boring & Milling Machine

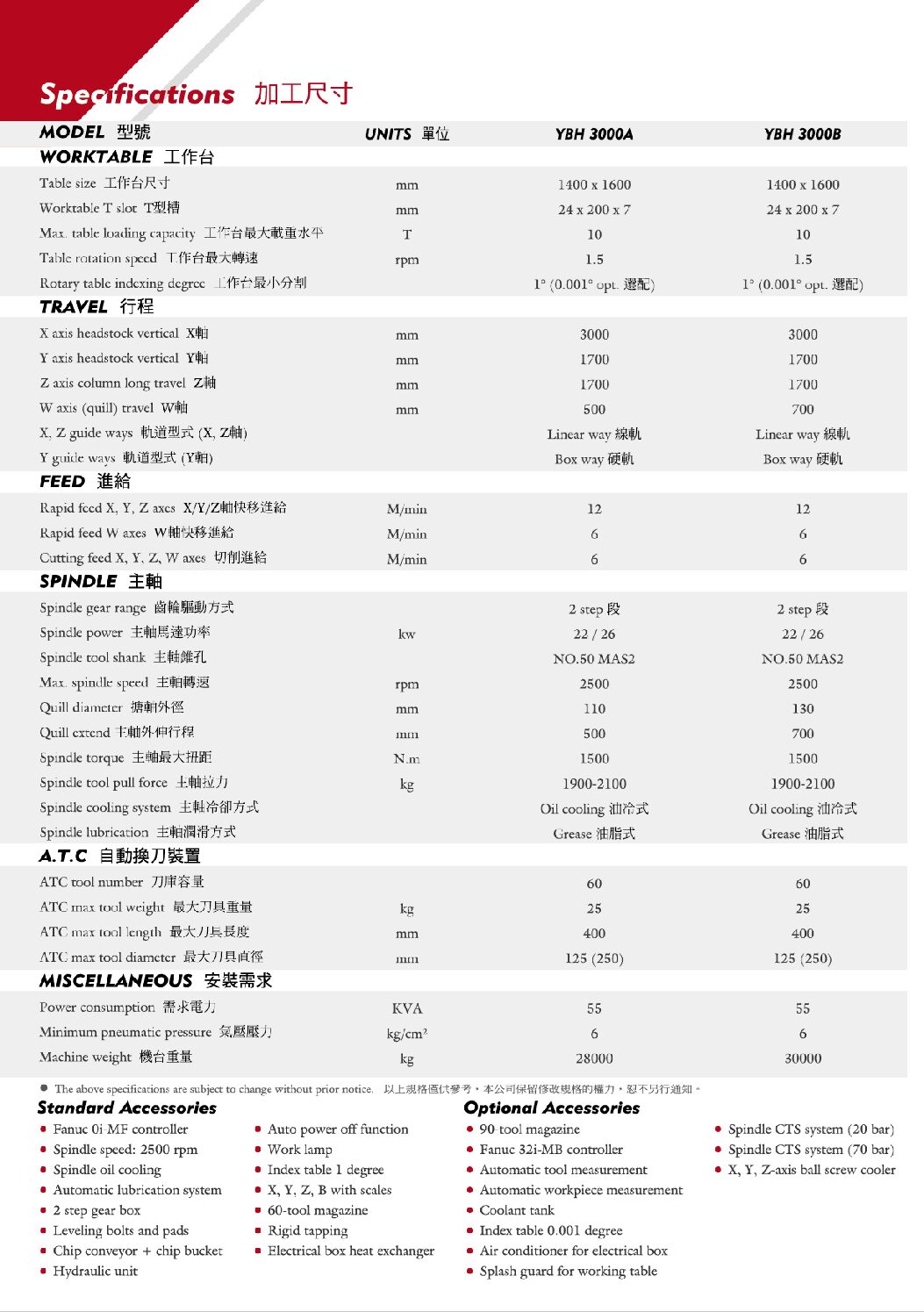

Specifications

| Make | HANNSA |

|---|---|

| Model | YBH 3000A, YBH 3000B |

Description

HANNSA – CNC Horizontal Boring & Milling Machine

YBH 3000A / YBH 3000B

Machine Features

- X, Y, Z-axis travel: 3000 x 1700 x 1700 mm.

- A moving column model for increasing efficiency.

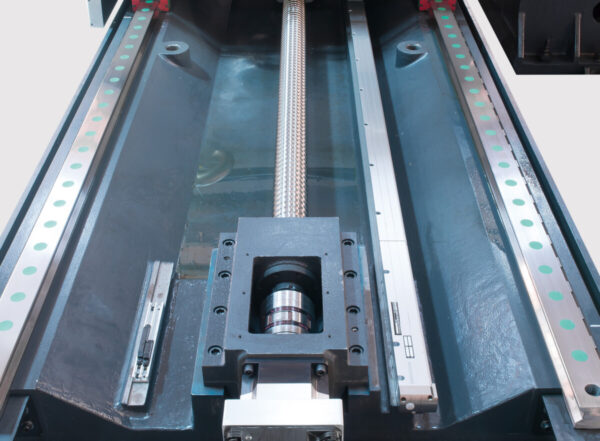

- Linear guideways on X, Z-axis. Box ways on Y-axis.

- W axis extension can reach 500mm without deflection problem.

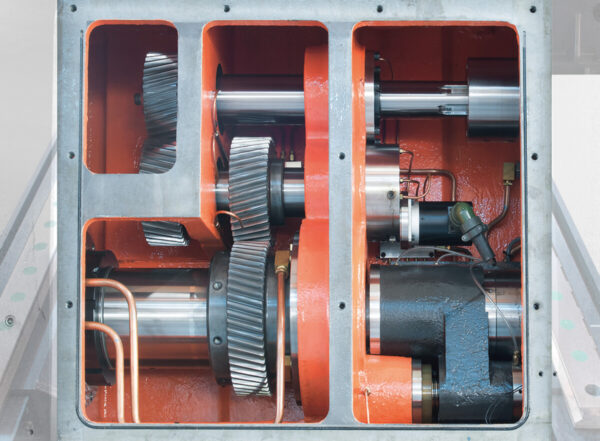

- The gearbox on the spindle head allows for a two-step speed change.

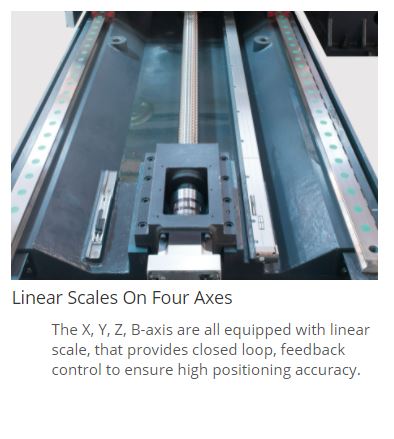

- X, Y, Z, B-axis are all equipped with linear scales for high positioning accuracy.

- Rotary table with 1° indexing is standard.

- Rotary table with 0,001° indexing is optional.

- Chain-type tool magazine with 60 tools.

- Massive base.

Superb Machine Structure to Exhibit Optimal Rigidity without Deformation

High Quality Cast Iron Stress Relieved

- The major structural parts of the machine are manufactured from high-quality cast iron, with internal stress relieved to achieve a deformation-free structure.

Moving Column

- The column is a moving type that provides an increase in efficiency.

Massive Base

- With a special design on the base structure, it helps to increase the structural rigidity.

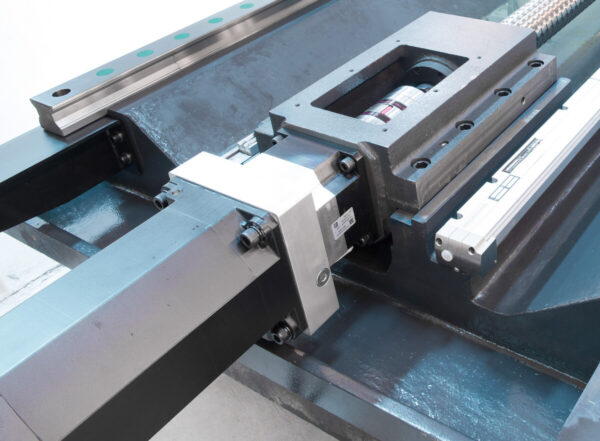

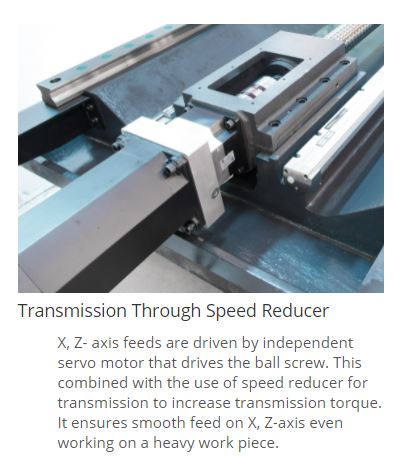

Slideway Type

- Linear guideways on X, Z-axis while Y-axis is designed with box ways. The combination design of slideways not only features a higher feed rate, but also ensures increased stability in heavy cutting.

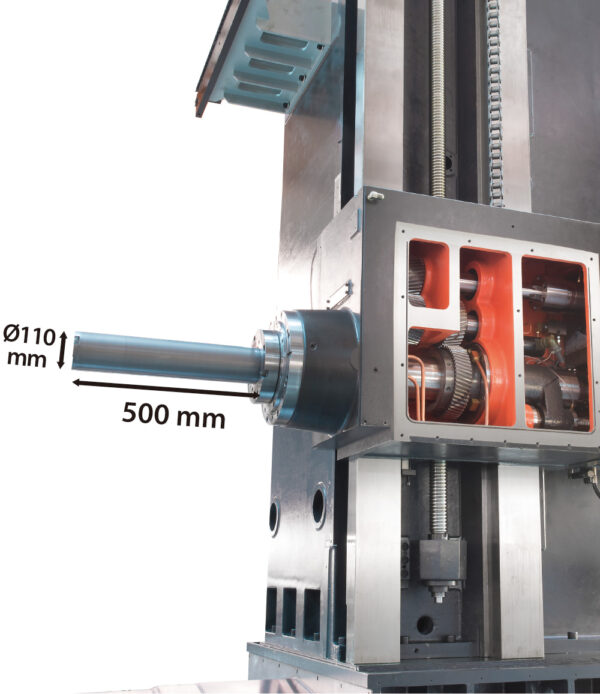

Gearbox of Spindle Head

- The spindle rotation is transmitted through a powerful gearbox, providing a high/low two-step speed change.

- The high-speed range is ideal for fine machining, while the low-speed range is applicable for heavy cutting.

- The gearbox is designed with a combination of spray-type and semi-oil bath cooling and lubrication system.

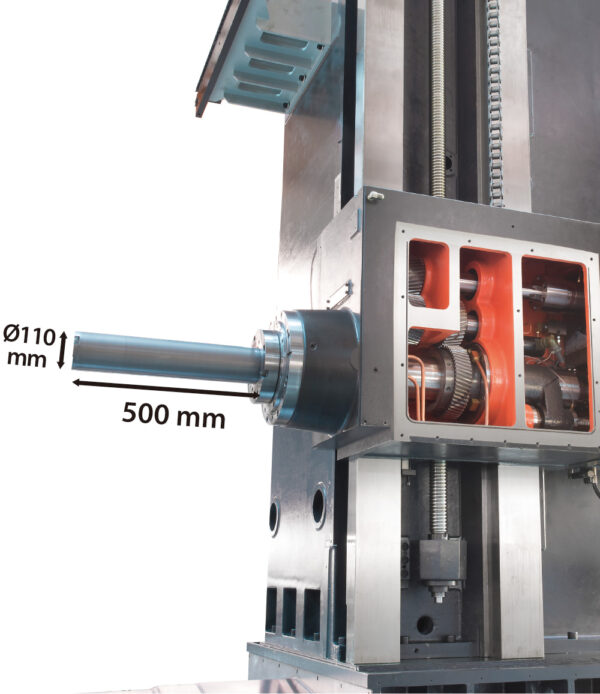

OnW-axis

- Diameter of W-axis: Ø110 mm.

- Max. travel of W-axis: 500 mm

- The spindle features high rigidity.

- There is no deflection, even the W-axis extends to a maximum distance.

- Deflection is controlled to within <0.02 mm.