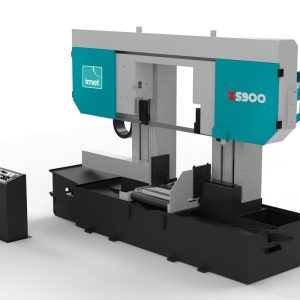

CHENLONG – G5125 – Aluminium Bar Vertical Cutting Band Saw Machine

Specifications

| Make | CHENLONG |

|---|---|

| Model | G5125 |

Description

CHENLONG – G5125 – Aluminium Bar Vertical Cutting Band Saw Machine

* This machine is mainly suitable for sawing small-sized aluminum plates, aluminum bars, etc. It has the advantages of narrow sawing gap, material saving, energy saving, high sawing precision, convenient operation and high production efficiency.

- Aluminium Bar Cutting Band Saw Machine Is A Vertical Band Saw For Cutting Aluminum Bars, Plates, Etc..

- Maximum Cutting Height Of 250mm

- Maximum Cutting Width(Depth) Of 350mm

Specifications

| Product Name | Aluminium Bar Cutting Band Saw Machine | |

| Brand | CHENLONG | |

| Model | G5125 | |

| Maximum Cutting Height | 250mm | |

| Maximum Cutting Width(Depth) | 350mm | |

| Working Table Moving Stroke | 500mm | |

| Size Of Blade (T×W×L) | 27×0.9 | |

| Blade Speed | 415, 830, 1430 m/min | |

| Blade Tension | Manual | |

| Guide Arm Movement And Locking | Manual | |

| Motors | Main Motor | 3kw |

| Hydraulic Motor | 0.37kw | |

| Water Pump Motor | 60w | |

* This aluminium bar cutting band saw machine is mainly composed of the following parts: base, main drive system, saw blade tensioning device, saw frame, saw blade guide device, table plate feeding system, cooling system, hydraulic system, electrical system, etc.

* The main drive system of the machine is composed of a main shaft, a driving wheel, etc. The main shaft and the driving wheel are directly connected, and the transmission is stable. The main drive is installed under the back of the saw frame and is directly driven by a vertical motor. The speed can be divided into three shifts: Slow, Medium and Fast.

* Work table feeding system: This system is mainly driven by hydraulic cylinder to make the work table move on the guide rail for actions like work feeding, rapid return, etc. The guide rail is guided by high-precision linear guide rail pair.

* This machine tool is designed with a set of electrical system, all electrical components are installed in the saw frame partition. In order to ensure safety, there is an interlock between each action. All actions are controlled by relay line, operated by buttons.