Machinery

-

Monthly Specials / In Stock / Demo / Used Equipment (21)

-

Aluminium Processing (64)

-

Bandsaws (59)

-

Briquetting (6)

-

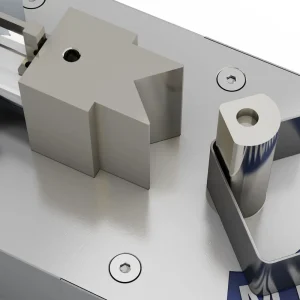

Busbar Processing Machines (8)

-

Cell Automation (1)

-

Cold Sawing (24)

-

End Forming & Deburring (16)

-

Horizontal Hydraulic Presses (3)

-

Laser Cutters (3)

-

Machining Centres & Lathes (10)

-

Non Mandrel Benders (12)

-

Plasma Cutters (8)

-

Radius Gauge Sets (2)

-

Robotics (40)

-

Section Rollers (18)

-

Sheet Metal Bending (8)

-

Software & Machine Retrofit (3)

-

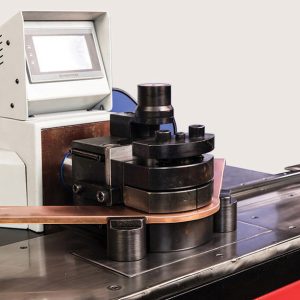

Tube Bending Machinery (46)

-

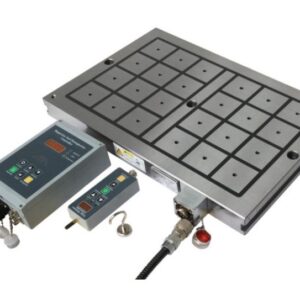

Work Holdings (7)

-

Wire & Rebar Machinery (33)