IMET – H 1200 NC F1500 – Automatic Double Column Bandsaw

Specifications

| Make | IMET |

|---|---|

| Model | H 1200 NC F1500 |

Description

IMET – H 1200 NC F1500 – Automatic Double Column Bandsaw

H 1200 NC F1500 is an automatic double column bandsaw suitable for straight cuts of carpentry works, pipes and solid materials, an affordable working tool for every professional user. The machine uses an innovative interface with 10″ touch screen display, guarantees for the highest cutting perfomances thanks to its rigid structure and 5° canted blade.

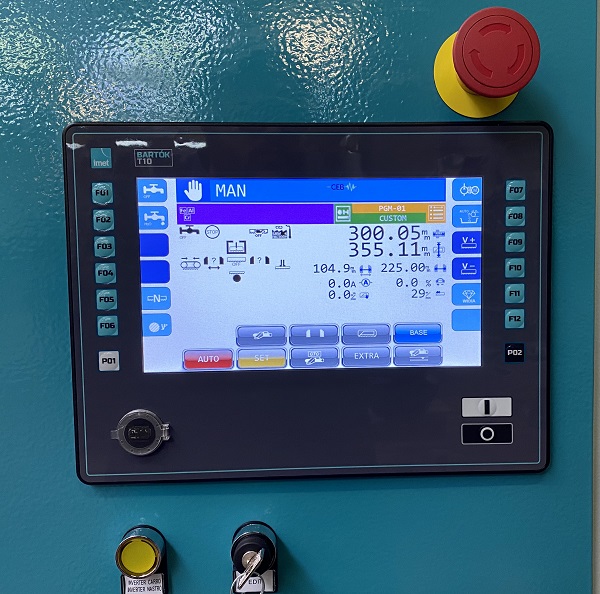

10″ Touch screen display

H 1200 NC has an easy and intuitive interface dedicate to optimize the user-experience: thanks, the CNC system and 10″ touch screen display the user can manage all the machine operative function, set up 99 cutting program and multiple cutting length on the same bar, set the number of feeder stroke, the number of pieces and blade speed. It’s also possible to do an auto diagnostic to detect errors.

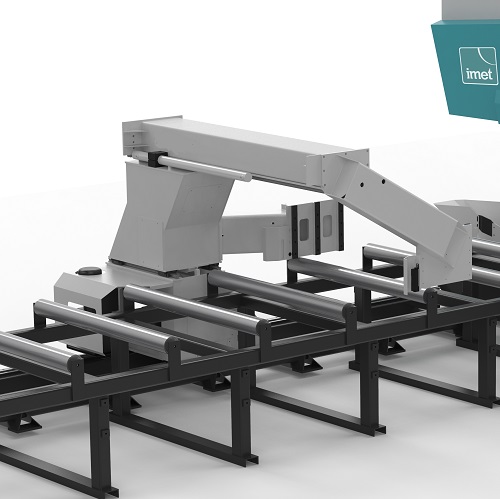

Material feeder

Feeder length is 3000mm with automatic stroke repetition, movement on linear ball guides. Minimum scrap end on the single cut is 300mm and 400mm with bundle cutting. H 1200 NC has a high positioning precision and stroke repetition thanks to the innovative system geared motor driven by inverted and controlled by a linear or encoder and mechanical clamping.

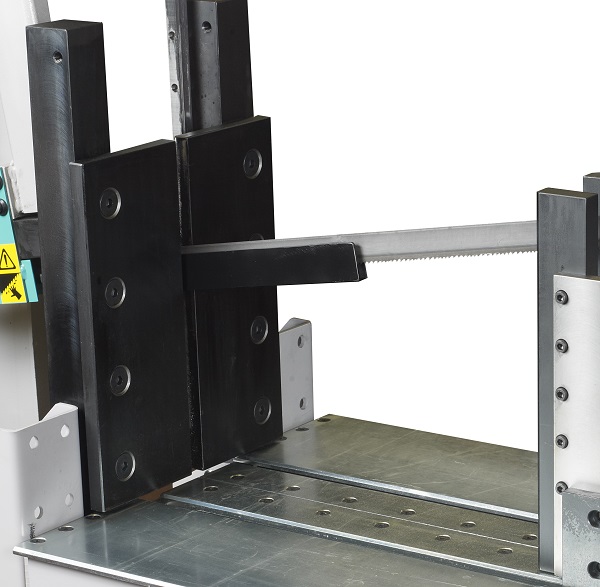

Rigid saw frame

H 800 NC has a big size, electro welded bow with rigid structure and big thickness. The massive structure helps reduce any vibration, binding or slowing during the cutting process, saving sawblade life and durability. High Cutting performances even on the biggest sections and full materials are provided by the 5° canted blade with 2000kg/cm2 blade tension.

Material detection system

H 800 and H 1200 are equipped with an automatic detection material system which also detect the first cut point thanks to a magnetic strip with encoder for material reading: the operator must set the material size on the panel control; the machine starts the automatic fast lowering of the saw frame up to the set value. This process allows to have a faster and easier approach to the material, helping saving time.

Blade speed

H 1200 NC F1500 is equipped with ESC electronic inverter for variable speed so that the machine is suitable to cut multiple materials (even bigger section and solids)

Vice

Tha machine has an hydraulic horizontal vice sliding on the working place. The vice uses a system with opening jaws on both sides to ease the loading of not-rectilinear bars.

Washing gun

Premium Line automatic bandsaws and semiautomatic and automatic Maxi Line bandsaws are standardly equipped with a washing gun dedicated to keep clean the working area and remove any residuals and remaining, allowing to keep the highest efficiency of the machine.

TECHNICAL INFORMATION

| Cutting capacity at 0° | Round: 680mm Square: 640mm Rectangular: 1250x600mm |

| Cutting capacity with bundle cutting | Max. 1000x330mm Min. 50x50mm |

| Cutting capacity at 0° for solid (C45)) | 400mm |

| Blade size | 8140x54x1.6mm |

| Blade speed | 7.5KW |

| Blade motor power | 15/90 m/min |

| Feeder length | 1500mm |

| Feeder motor power | 1.5KW |

| Minimal scrap-end | 300mm |

| Minimum cutting length | 100m |

| Working area height | 855mm |

| Size | 4250x4000x2750mm |

| Weight | 4955kg |

![IMET – KTECH 352 – F1200 – Automatic bandsaw for structural steels [Made In Italy] IMET - KTECH 352 - F1200 - Automatic bandsaw for structural steels [Made In Italy]](https://www.delahenty.com.au/newwp/wp-content/uploads/2024/10/IMET-KTECH-352-F1200-MAXI-LINE-image01-300x300.jpg)