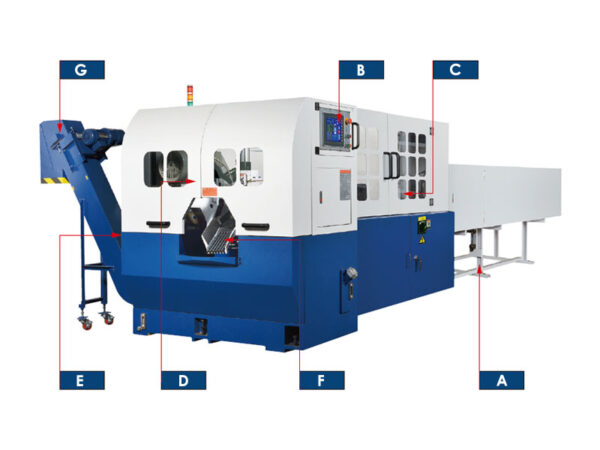

FONG HO – THC-B70NC – Fully Automatic Tungsten Carbide Sawing Machine

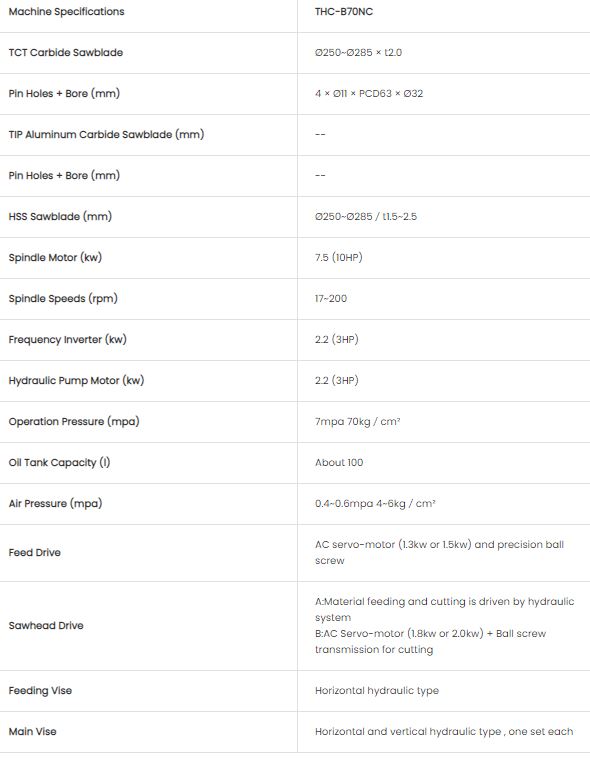

Specifications

| Make | FONG HO |

|---|---|

| Model | THC-B70NC |

Description

FONG HO – THC-B70NC – Fully Automatic Tungsten Carbide Sawing Machine

Fully Automatic Tungsten Carbide Sawing Machine

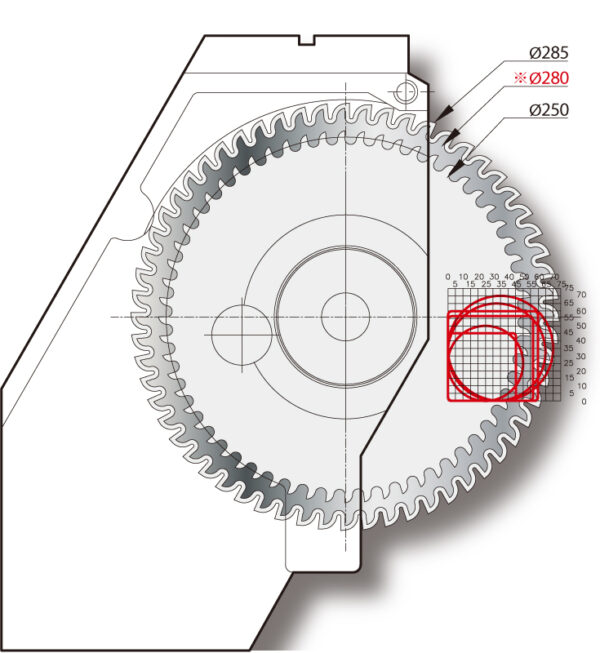

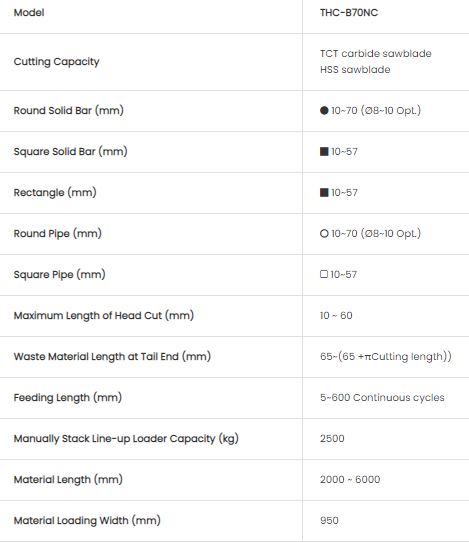

The THC-70NC, THC-B90NC, THC-130NC, THC-165NC high speed tungsten carbide sawing machine is designed and engineered to create optimum cutting performance. It features high speed, high efficiency, smooth surface of cut and high accuracy.

The THC-70NC, THC-B90NC, THC-130NC, THC-165NC is especially ideal for cutting solid bars and angular steel. Also suitable for cutting steel pipe by using a HSS sawblade.

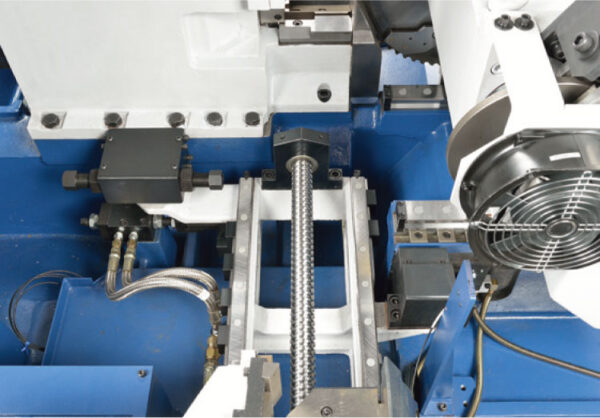

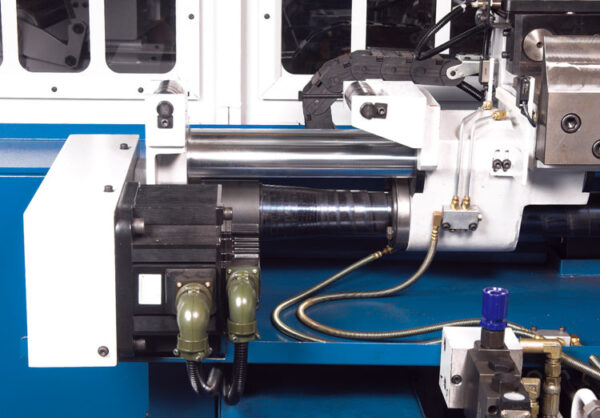

- Servo-motor drive+ball screw feed transmission (Standard)

- Sawhead driven by Servo-motor+Ball screw transmission for cutting (optional)

- Feeding safety guard (optional)

- Fully feeding safety guard (optional)

Full Equipment Introduction

- Fully automatic extra hard tungsten carbide sawing machine + Manual stack line up loader or automatic magazine loader (opt)

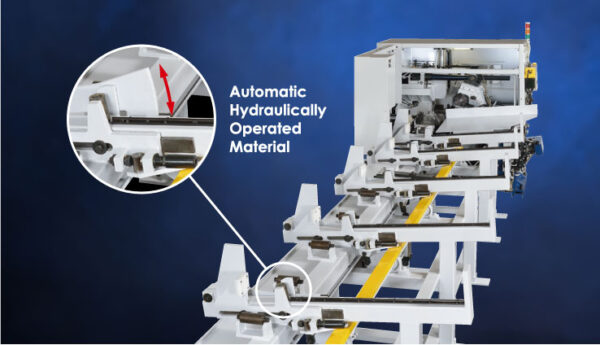

- Automatic hydraulically operated material lifting

- Servo-motor drive+ ball screw feed transmission

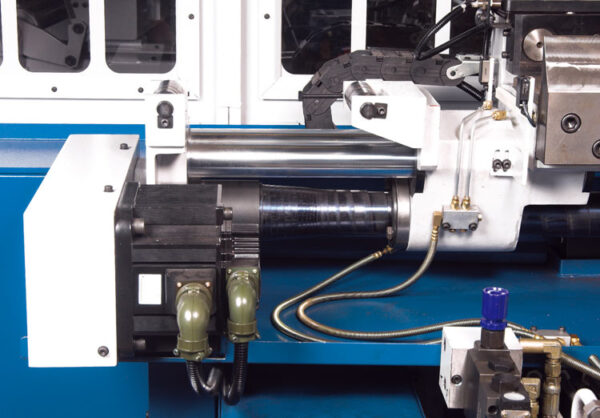

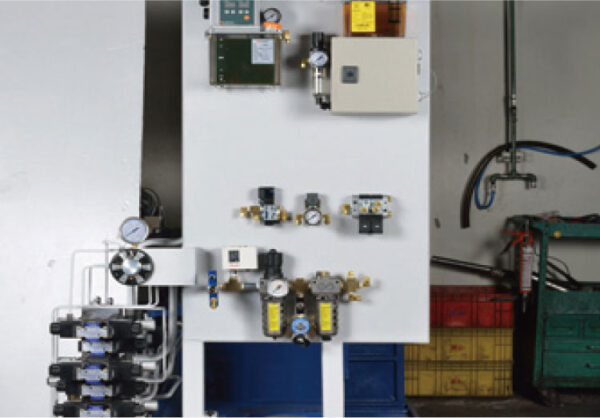

- Hydraulically operated vise feed

- Main and top hydraulic vise

- Hydraulic driven sawhead feed for cutting motion (standard)

- Sawhead driven by servo-motor+ball screw transmission for cutting (optional)

- Head and tail pieces separate automatically.

- Automatic material outfeed.

- The first and second workpieces are outfeed separately.

- Head and end pieces are outfeed at left and right sides. (opt)

- Continuous motion cycles

- Automatic materisl collection device (optional)