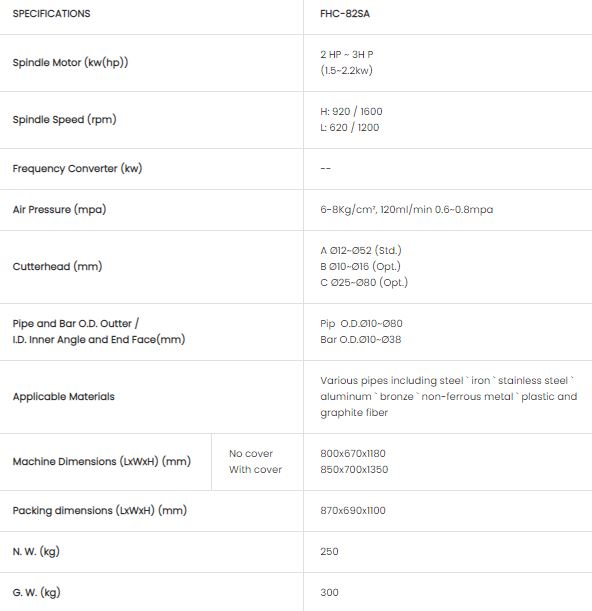

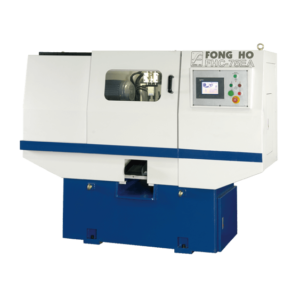

FONG HO – FHC-82SA – Metal Circular Pipe / Bar Stock End Chamfering Machine

Specifications

| Make | FONG HO |

|---|---|

| Model | FHC-82SA |

Description

FONG HO – FHC-82SA – Metal Circular Pipe / Bar Stock End Chamfering Machine

- Manual material loading and automatic cutter feeding / retracting provides high operational speed and greatly increase productivity.

- The semi-automatic model has 2-step feed speed. The first step feed is high speed, then the second step feed speed is adjustable to produce clean and smooth cutting results.

- Changing sizes of cut are conveniently made by simply adjusting and changing cutterhead and clamp.

- Speed change on model 50SA、85SA is made through pulley for chamfering various materials of workpieces ensuring long service life of cutter.

- Models 110SA and 150SA employ-change motor to change speed for chamfering various materials of workpiece, ensuring long service life of cutter.

Automatic Model

Motion cycle includes automatic material infeed through a channel (automatic feeder is optional). Automatic cutting feeding/retracting and automatic workpiece outfeed. Continuous motion cycles provide high machining speed, high accuracy, reduced labor requirement while greatly upgrading productivity.

Standard Equipment:

- Standard cutter head x 1 set

- Circular clamping mold x 1 set