- Home

- Our Company

- Latest News

- Machinery

- Monthly Specials & Used Equipment

- Aluminium Processing

- Bandsaws

- Briquetting

- Busbar Processing Machines

- Cold Sawing

- End Forming & Deburring

- Horizontal Hydraulic Presses

- Laser Cutters

- Machining Centres & Lathes

- Non Mandrel Benders

- Plasma Cutters

- Radius Gauge Sets

- Robotics

- Section Rollers

- Sheet Metal Bending

- Software & Machine Retrofit

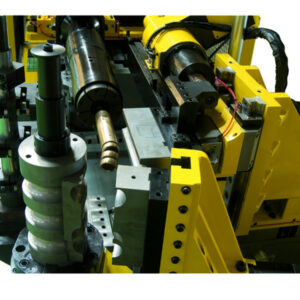

- Tube Bending Machinery

- Wire & Rebar Machinery

- Work Holdings

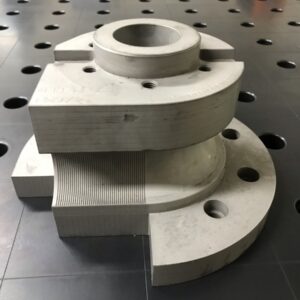

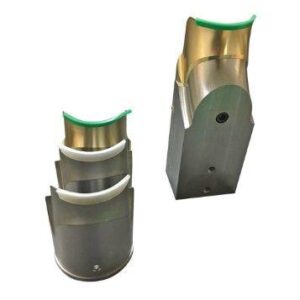

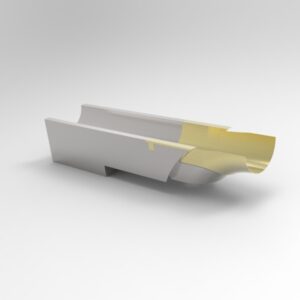

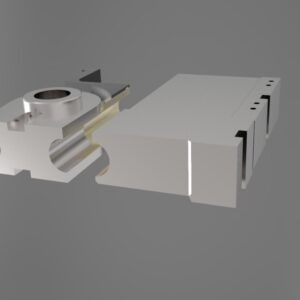

- Tooling

- Services & Support

- Contact Us